A recent Performance Footing case study revealed that arenas equipped with BaseCore geocell technology returned to rideable condition 65% faster after heavy storms compared to traditional drainage systems. For the thousands of equestrians who cancel training sessions every time clouds gather, this statistic represents the difference between a functional facility and an expensive mud pit. This guide examines how BaseCore’s geocell technology transforms arena drainage from a persistent headache into a one-time installation that delivers decades of reliable performance.

What Free-Draining Arena Technology Is—Through Real Implementation

The concept of cellular confinement for ground stabilization originated with the U.S. Army Corps of Engineers in 1975. According to Wikipedia’s comprehensive documentation on cellular confinement systems, engineers sought to devise a method for building tactical roads over soft ground and discovered that sand-confinement systems performed significantly better than conventional crushed stone sections.

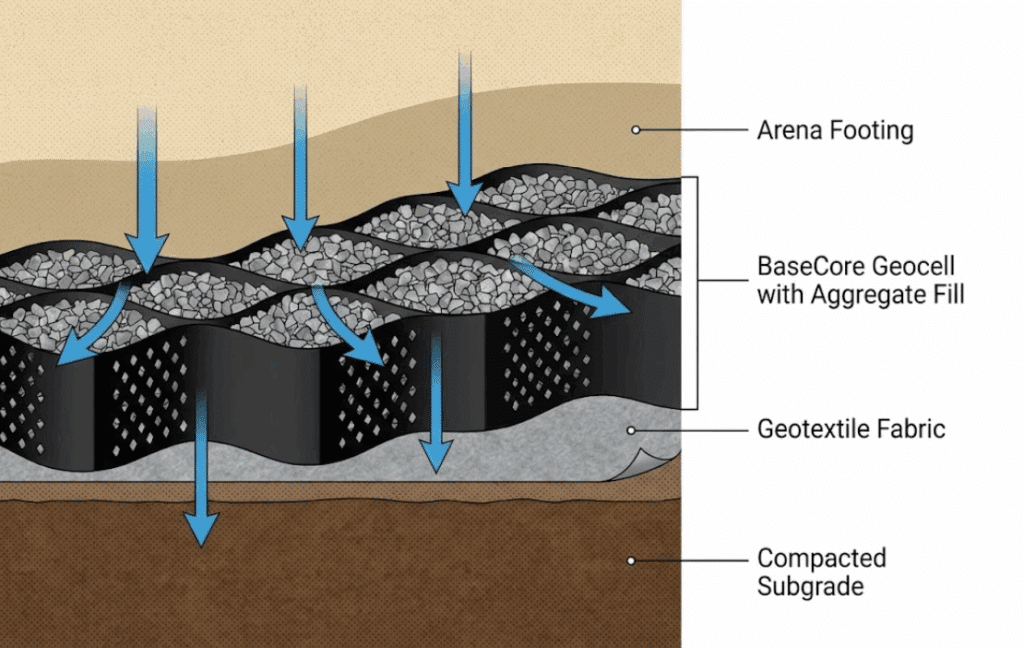

Performance Footing adapted this military-grade technology specifically for equestrian applications with BaseCore. The product consists of three-dimensional honeycomb structures made from high-density polyethylene (HDPE) that expand on-site to create a cellular foundation. When filled with aggregate, these cells create what engineers call “apparent cohesion” in non-cohesive materials—essentially turning loose gravel into a unified, stable surface.

Early research documented by Bathurst and Jarrett in 1988 found that cellular confinement reinforced gravel bases are “equivalent to about twice the thickness of unreinforced gravel bases.” This finding explains why BaseCore installations require only 4 inches of aggregate compared to the 6-12 inches needed for traditional arena bases.

The practical application becomes clear when examining water movement. A properly installed BaseCore system can move water at rates of 4-6 inches per hour, according to Performance Footing’s technical specifications. This drainage capacity exceeds even the heaviest recorded rainfall events in most regions, ensuring arenas remain rideable regardless of weather conditions.

How Performance Footing Facilities Achieved Results

The Oregon Dressage Facility Implementation

A dressage facility in Oregon’s high-rainfall region provides one of the most documented transformations using BaseCore technology. Before installation, the facility owner faced a frustrating reality: traditional French drain systems failed to prevent standing water, resulting in frequent canceled lessons and deteriorating footing conditions.

The facility selected BaseCore HD specifically because of its cell dimensions. The 3-inch BaseCore HD panels feature cells measuring 7.2 inches by 6.0 inches—the smallest in the market at almost 50% smaller than other geocell products, according to Performance Footing’s product specifications. This tighter cell structure proved critical for equestrian safety, as larger cell openings in alternative products can potentially trap horse hooves.

Performance Footing’s installation team prepared the site by first compacting and grading the native soil, then laying commercial-grade 6oz non-woven geotextile fabric across the entire arena footprint. The fabric, priced at $899 for 12.5×360 feet rolls, serves multiple purposes: preventing weed growth, separating base materials from native soil, and enhancing drainage efficiency.

The BaseCore HD panels arrived in a collapsed configuration and expanded accordion-style during installation. Workers secured adjacent panels using BaseClips—Performance Footing’s engineered connection system designed for long-term load distribution. This differs from some installation methods that use zip ties or bent rebar stakes, both of which present durability and safety concerns.

After filling the cells with 4 inches of 3/8-inch minus crushed rock and compacting with a vibrating plate compactor, the arena was ready for footing application. The facility documented their results: 68% fewer canceled lessons in the first year compared to their previous five-year average.

The Florida Hunter/Jumper Arena Case Study

A hunter/jumper arena in Florida faced different but equally challenging conditions—intense storm events that could dump several inches of rain in hours. Performance Footing’s documentation shows this installation withstood a 4-inch rainfall event and returned to rideable condition within 3 hours.

The success stemmed from BaseCore’s fundamental design principle: creating pathways for water to move laterally through the arena base without extensive pipe systems. Traditional French drain installations require excavation, perforated pipe placement, and careful grading toward drain outlets. BaseCore’s perforated cell walls accomplish similar water management through the cellular structure itself.

Measurable Outcomes and ROI

Cost Analysis: BaseCore vs. Traditional Methods

Performance Footing’s 2025 pricing analysis reveals the economic case for BaseCore technology. For a standard 60×120 foot arena:

BaseCore Installation Costs:

- BaseCore panels (30 units at $135 each for 9×24 feet): $4,050

- Geotextile fabric: $899

- Aggregate fill (4 inches of 3/8″ minus): $2,000-3,500

- Total base investment: $7,000-8,500

Traditional Base Construction:

- Aggregate material (6-12 inches): $10,000-15,000

- French drain system: $5,000-10,000

- Professional installation labor: Additional premium

- Total traditional investment: $15,000-25,000+

The 50% reduction in aggregate requirements alone generates $5,000-10,000 in immediate savings on a standard arena.

Long-Term Maintenance Savings

Traditional arena bases require reconstruction every 10-15 years due to material migration, drainage failures, and surface irregularities, according to Performance Footing’s analysis. BaseCore’s UV, chemical, weather, and corrosion-resistant construction supports projects for over 75 years—eliminating multiple reconstruction cycles over a facility’s lifetime.

Maintenance savings stem from eliminated regrading costs, reduced footing replacement frequency, and decreased labor for drainage upkeep. Traditional bases require quarterly grading and annual aggregate addition, while BaseCore’s cellular confinement keeps materials in place indefinitely.

Health and Safety Metrics

Proper drainage directly impacts horse health and safety. According to industry research cited by DB Horse Stable, 60% of arena-related accidents stem from neglected surfaces. Poor drainage creates the inconsistent footing conditions—soft spots, unexpected deep areas, and slippery zones—that contribute significantly to these incidents.

Standing water in arenas compromises surface integrity and creates conditions for hoof problems such as thrush, abscesses, and soft tissue injuries, according to documentation from horse arena construction specialists. Horses working on inconsistent, poorly drained surfaces face elevated injury risks from unstable footing.

Performance Recovery Metrics

The headline statistic—65% faster return to rideable condition after storms—represents the most practical benefit for working facilities. When traditional arenas require days to dry after moderate rainfall, BaseCore installations return to use within hours.

This recovery speed translates directly to revenue protection for commercial facilities. A boarding barn with 20 horses generating $50 per lesson loses $1,000 for every day of weather cancellations. If BaseCore eliminates just 20 additional riding days annually compared to traditional drainage, the system pays for itself within 3-4 years through preserved revenue alone.

Comparing Industry Approaches to Arena Drainage

Traditional French Drain Systems

The herringbone drainage system has long been considered the standard for equestrian arenas. This design uses a main 100-150mm diameter pipe running across the arena center, with 75-100mm diameter perforated pipes connecting at 45-degree angles to collect and redirect water.

French drains work effectively when properly installed and maintained. However, several limitations affect long-term performance. Root intrusion can block perforated pipes over time. Soil migration gradually reduces drainage capacity. Installation requires precise grading toward drain outlets—any errors create new pooling zones rather than solving existing ones.

Performance Footing’s analysis indicates traditional french drain systems cost 30-40% more than equivalent BaseCore installations when accounting for excavation, pipe materials, and specialized installation labor.

Grading and Crown Methods

Many facility owners attempt to solve drainage through surface grading alone. The crown method creates a high point down the arena center with gentle 1-2% slopes falling toward the perimeter. This approach can move surface water effectively but does nothing for water that has already penetrated the footing layer.

Laser grading uses precision equipment with laser receivers to create exact surface contours accurate to fractions of an inch. While valuable for any arena installation, grading addresses only surface flow—not the subsurface drainage that determines long-term arena performance.

Aggregate-Only Base Construction

Traditional aggregate bases use 4-6 inches of crushed rock compacted by heavy rollers to create a permeable foundation. This approach works in ideal soil conditions but fails in clay-heavy or poorly draining native soils.

The fundamental problem: loose aggregate migrates under load. Horse hooves striking the surface create lateral forces that push aggregate outward, creating the deep spots and valleys that plague older arenas. Without cellular confinement, aggregate bases require periodic regrading and material addition—ongoing costs that accumulate over the arena’s lifetime.

The BaseCore Geocell Approach

BaseCore addresses the limitations of all previous methods through cellular confinement. Each cell acts as a miniature retaining wall, preventing the lateral movement that causes traditional surfaces to fail. The three-dimensional structure provides strength that flat materials cannot match.

Performance Footing’s documentation explains the engineering principle: imagine walking across loose marbles versus marbles confined in individual compartments. The confined marbles create stability because they cannot shift laterally. BaseCore accomplishes the same effect with aggregate, creating what engineers call a stable composite mattress.

Practical Implementation Guide: Step-by-Step BaseCore Installation

Step 1: Site Evaluation and Preparation

Performance Footing recommends starting with a thorough site evaluation. Document problem areas during different weather conditions—these photographs help professionals understand unique challenges and inform installation planning.

Proper preparation begins with removing topsoil and vegetation to expose subgrade soil. Performance Footing notes that some locations with particularly poor drainage benefit from adding a 4-inch drainage rock layer over compacted native soil before BaseCore installation.

Compact the native soil or subgrade using appropriate equipment until the surface achieves road-like firmness. Grade the area to establish proper slope—typically 1-2% toward the perimeter or natural drainage points.

Step 2: Geotextile Fabric Installation

Lay commercial-grade 6oz non-woven geotextile fabric across the entire arena footprint. This fabric layer serves critical functions: separating base materials from native soil, preventing weed growth, and enhancing overall drainage efficiency.

Overlap fabric seams by at least 12 inches to prevent soil migration through gaps. Some installers use geotextile adhesive to secure overlaps, though proper overlap alone typically provides adequate separation.

Step 3: BaseCore Panel Deployment

BaseCore panels arrive collapsed for shipping efficiency. Expand each panel accordion-style to its full dimensions—standard BaseCore panels expand to 9×24 feet, while HD panels reach 10×12 feet.

Position panels across the geotextile layer, aligning edges for connection. Secure adjacent panels using BaseClips, Performance Footing’s engineered connection system. These heavy-duty clips provide secure, seamless connections without the sagging or shifting associated with zip-tie methods.

Anchor panels to the subgrade using BaseCaps, which sit flush and remain safe for foot and vehicle traffic. This differs from bent rebar stakes that create trip hazards and can puncture tires.

Step 4: Aggregate Fill and Compaction

Fill expanded BaseCore cells with appropriate aggregate—Performance Footing recommends 3/8-inch minus crushed rock for equestrian applications. The “minus” designation indicates the material includes particles from the maximum size down to rock dust, which provides superior compaction within cells.

Start filling from one corner, distributing aggregate evenly across the geocell surface using a skid steer or wheelbarrows. The small cells of BaseCore HD trap and confine aggregate, preventing lateral movement and creating a unified base layer.

Compact filled cells using a vibrating plate compactor, ensuring material settles completely both within and above the cells. The target is 4 inches of compacted aggregate measured from the top of the geocell structure.

Step 5: Footing Application

With the BaseCore base complete, apply chosen arena footing materials according to discipline requirements. The stable, free-draining base supports any footing type—sand, sand-fiber blends, or proprietary mixtures like Performance Footing’s ArenaGreen.

The cellular base structure prevents the footing migration that plagues traditional installations, maintaining consistent depth across the arena surface over time.

Tools and Materials Summary

Required Materials:

- BaseCore or BaseCore HD panels (calculate based on arena dimensions)

- 6oz non-woven geotextile fabric

- 3/8″ minus crushed rock aggregate

- BaseClips connection clips

- BaseCaps anchor caps

- Chosen arena footing

Required Equipment:

- Excavation equipment (if site preparation needed)

- Compaction equipment (plate compactor or roller)

- Material distribution equipment (skid steer, wheelbarrows)

- Basic hand tools (utility knife for fabric cutting)

Timeline Expectations

Performance Footing documentation indicates that installation proceeds significantly faster than traditional methods—one case study showed 40% less time than estimated for comparable traditional systems. A standard arena can be completed in 1-3 days depending on site conditions and crew size.

The company notes that as few as 2 people with simple tools can build a reliable base, though larger crews naturally accelerate the timeline.

Conclusion

The Oregon dressage facility that opened this guide now operates with 68% fewer weather-related cancellations annually. Their BaseCore installation has withstood multiple severe weather events with no signs of erosion or movement—performance that validates the technology’s military origins and 75+ year design lifespan.

The measurable outcomes across documented installations paint a consistent picture: 65% faster recovery after storms, significant reductions in weather-related cancellations, and elimination of the 10-15 year reconstruction cycles that burden traditional arena owners.

For facility owners ready to transform their drainage challenges into lasting solutions, the path forward is clear. Contact Performance Footing’s arena specialists at (877) 835-0878 for a free consultation that evaluates your specific site conditions and provides customized recommendations for achieving the free-draining arena that serves your horses and your schedule for decades to come.

FAQ Section

How long does BaseCore installation take for a standard arena?

Performance Footing documentation indicates installation proceeds approximately 40% faster than traditional drainage systems. A standard 60×120 foot arena typically requires 1-3 days depending on site conditions and crew size.

Can I install BaseCore myself without professional help?

Yes. Performance Footing states that 2 or more people with simple tools and equipment can build a reliable base without formal training. The company provides installation guides covering their straightforward 6-7 step process.

How much aggregate does BaseCore save compared to traditional methods?

BaseCore reduces aggregate requirements by up to 50%. Traditional bases need 6-12 inches of material; BaseCore installations require only 4 inches of 3/8-inch minus crushed rock to fill and cap the cells.

What is the expected lifespan of a BaseCore arena base?

Performance Footing’s UV, chemical, weather, and corrosion-resistant HDPE construction supports projects for over 75 years. This eliminates the 10-15 year reconstruction cycles typical of traditional arena bases.

Will BaseCore work in clay-heavy soil conditions?

Yes. BaseCore’s cellular confinement prevents the drainage failures that occur when aggregate migrates into clay soils. The geotextile fabric layer provides additional separation, and some sites with particularly poor drainage benefit from a 4-inch drainage rock layer before BaseCore installation.

This article references publicly available information from Performance Footing including official product documentation and technical specifications dated 2022-2025. Historical geocell information sourced from Wikipedia documentation on cellular confinement systems and industry publications including Geosynthetics Magazine. Performance metrics cited are from Performance Footing’s published materials. Results may vary based on soil conditions, climate, arena size, and implementation approach. For current product specifications, pricing, and personalized recommendations, consult Performance Footing directly at performancefooting.com.