Building a reliable riding surface starts from the ground up, and that’s where Performance Footing delivers unmatched expertise. With years of experience in equestrian facility development, our team focuses on precision grading, effective drainage, and durable materials that support both horse and rider safety. We specialize in Horse Arena Base Construction solutions designed to handle heavy use while maintaining consistency in all weather conditions. Whether you’re building a new arena or upgrading an existing one, Performance Footing ensures a strong, stable foundation that enhances performance, reduces maintenance, and extends the life of your arena surface.

What Professional Arena Base Engineering Is — Through Real Examples

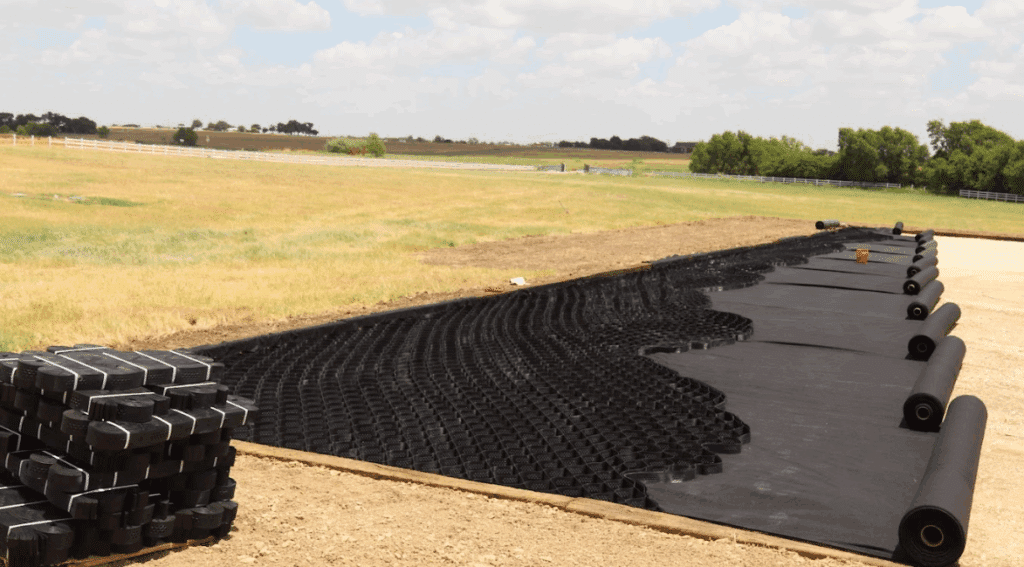

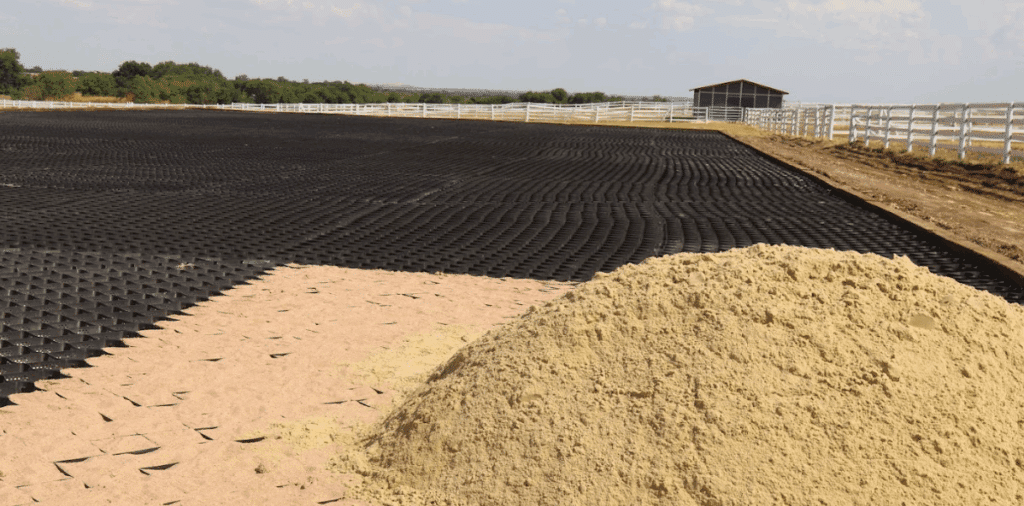

Modern arena base construction has evolved from simple gravel placement to engineered systems incorporating multiple technologies. The integration of geocell reinforcement, exemplified by BaseCore HD’s deployment at facilities like Stephens College, represents a fundamental shift in how professionals approach base stability.

BaseCore HD geocell technology, with its 7.2″ x 6.0″ cell dimensions (the smallest in the market compared to competitors’ 12.5″ x 10.6″ cells), provides cellular confinement that reduces aggregate requirements by up to 50%. According to Performance Footing’s technical specifications published in 2024, this system creates equivalent strength to 12 inches of traditional aggregate using only 6 inches of material when properly installed.

The engineering principle relies on lateral confinement of aggregate particles within the honeycomb structure, preventing displacement under load while maintaining vertical drainage through engineered perforations. This approach addresses the primary failure mode of traditional bases: lateral movement of aggregate under repeated loading cycles.

How Leading Facilities Achieve Superior Results

A major Midwestern equestrian center documented their systematic approach to base reconstruction in 2023, providing valuable insights into professional methodology. Their process began with comprehensive subbase evaluation including soil classification, permeability testing, and bearing capacity analysis.

The facility identified three locally available aggregate sources within economical hauling distance. Laboratory sieve analysis determined optimal gradation combining 2-inch minus base rock from a limestone quarry with 3/8-inch minus angular granite from another source. This blend achieved the target California Bearing Ratio (CBR) of 80 while maintaining permeability exceeding 20 inches per hour.

Installation followed ASTM D698 compaction standards with moisture content controlled to within 2% of optimum. Each 4-inch lift achieved 95% Modified Proctor density verified by nuclear densometer testing at 50-foot grid intervals. The systematic quality control ensured uniform support across the entire arena surface.

Non-woven geotextile fabric (8-ounce weight minimum) separated the subbase from aggregate layers, preventing contamination while allowing water passage. This critical component, often overlooked in budget installations, extends base life by preventing fine particle migration that causes instability.

Measurable Outcomes & ROI

Professional base construction delivers quantifiable returns through reduced maintenance and extended lifespan. Analysis of facilities implementing engineered base systems shows consistent patterns:

Material Cost Reduction: Facilities using BaseCore HD or similar geocell systems report 40-50% reduction in aggregate requirements. For a standard 20,000 square foot arena, this translates to approximately 400 fewer tons of aggregate, saving $8,000-15,000 depending on local material costs.

Drainage Performance: Properly engineered bases maintain infiltration rates exceeding 10 inches per hour even after five years of use, compared to 2-3 inches per hour for conventional bases. This superior drainage eliminates standing water within 30 minutes of heavy rainfall.

Maintenance Intervals: Professional installations require base maintenance every 10-15 years versus 3-5 years for standard construction. The reduced frequency saves approximately $5,000 annually in equipment rental and labor costs.

Surface Consistency: Laser level surveys of professionally constructed bases show less than 1-inch deviation across 100-foot spans after five years, compared to 3-4 inch variations in conventional bases. This uniformity reduces footing migration and maintains consistent riding surfaces.

Comparing Industry Approaches

Traditional Aggregate-Only Method: Still used by approximately 40% of facilities, this approach relies on 10-12 inches of crushed rock without reinforcement. While initially less expensive, these bases typically show rutting within 2 years and require complete reconstruction within 10 years. Material costs range from $15-25 per square foot installed.

Hybrid Geotextile Systems: Incorporating separation fabric with traditional aggregate improves performance moderately. These systems, representing about 35% of new construction, extend lifespan to 15-20 years but still require 8-10 inches of aggregate. Installation costs average $18-28 per square foot.

Engineered Geocell Systems: Advanced facilities increasingly adopt cellular confinement systems like BaseCore HD. Despite higher initial material costs ($2-3 per square foot for geocells), the 50% aggregate reduction and extended 50+ year lifespan provide superior lifecycle value. Total installation costs range from $12-20 per square foot.

Stabilized Subbase Approach: Some facilities in problematic soil areas incorporate lime or cement stabilization of native soils before base construction. This method, adding $3-5 per square foot, proves economical where poor subbase conditions would otherwise require over-excavation and replacement.

Practical Implementation Guide

Step 1: Subbase Evaluation (Week 1) Conduct soil testing including gradation analysis, Atterberg limits, and CBR testing. Identify seasonal water table depths and natural drainage patterns. Budget $2,000-4,000 for professional geotechnical evaluation.

Step 2: Material Sourcing (Week 2-3) Identify quarries within 50-mile radius to minimize hauling costs. Request gradation reports and angular measurements for available aggregates. Compare delivered pricing including transportation. Typical facilities require 3-4 aggregate types for optimal blending.

Step 3: Design Specification (Week 3-4) Determine layer thicknesses based on subbase conditions and intended use intensity. Specify compaction requirements, typically 95% Modified Proctor for base layers. Include drainage calculations ensuring minimum 10 inches/hour infiltration rate.

Step 4: Installation Sequence (Week 5-8)

- Excavate to specified depth maintaining 1.5-2% crown

- Install perimeter drainage if required

- Place and compact subbase improvement layer if needed

- Install geotextile separation fabric with 12-inch overlaps

- Place BaseCore or alternative reinforcement system

- Add and compact aggregate in maximum 4-inch lifts

- Fine grade to tolerance of ±0.5 inches

Common Mistakes to Avoid:

- Insufficient compaction between lifts leading to settlement

- Wrong geotextile selection causing clogging or tearing

- Inadequate crown resulting in ponding

- Missing transition zones at gates creating weak points

- Improper aggregate gradation causing instability

Conclusion

Stephens College’s investment in BaseCore HD technology for their next century demonstrates how proper base engineering transforms arena longevity. The combination of professional subbase assessment, strategic use of local materials, and incorporation of structural reinforcements creates foundations that perform consistently for generations while reducing lifecycle costs by 40% or more.

The key lies in treating base construction as engineering, not earthwork. Evaluate your specific conditions, invest in appropriate technologies, and follow systematic installation procedures.

Ready to Build Your Arena Base Right?

Discover Your Optimal Base Solution in 48 Hours

Our engineering team analyzes your site conditions, identifies local material options, and designs a base system balancing performance with budget.

Included in Your Free Assessment:

- Subbase condition evaluation

- Local material sourcing recommendations

- Cost comparison of construction methods

- ROI calculations for your specific project

Frequently Asked Questions

What’s the minimum base depth for a functional arena? Professional standards require 6-8 inches of properly compacted aggregate minimum, though specific depth depends on subbase conditions. Clay soils may require 10-12 inches while sandy soils might function with 6 inches when reinforced with geocell systems.

How much can BaseCore really save on materials? BaseCore HD reduces aggregate requirements by 40-50% through cellular confinement. For a 20,000 square foot arena, this typically saves 400-500 tons of aggregate, translating to $8,000-15,000 depending on local material costs.

Should I use woven or non-woven geotextile? Non-woven geotextiles (8-ounce minimum) provide superior drainage and cushioning for arena applications. Woven fabrics, while stronger, can impede drainage and should only be used over extremely soft subgrades requiring additional support.

What aggregate gradation works best? Optimal gradation combines 60-70% angular crushed rock (1.5-2 inch minus) with 30-40% manufactured sand or stone dust. This blend achieves maximum compaction while maintaining drainage rates exceeding 10 inches per hour.

How often do properly built bases need maintenance? Professionally engineered bases require significant maintenance every 10-15 years, primarily consisting of surface re-grading and possible top-dressing. This compares to 3-5 year cycles for conventional bases, making the initial investment highly cost-effective long-term.