Traditional arena bases require complete reconstruction every 10-15 years due to material migration, drainage failures, and surface irregularities — a cycle that costs facility owners thousands in repeated investments, according to Performance Footing’s 2025 construction analysis. This expensive failure pattern stems from one fundamental problem: arenas designed without precision consideration of discipline requirements, geographic conditions, and engineered layering systems. In this comprehensive guide, you will discover how to plan arena projects from site assessment through final construction, design for specific riding disciplines, engineer proper drainage systems, and select appropriate base materials and layering approaches that deliver 75+ year performance.

What Precision Horse Arena Design Requires — The Planning Foundation

Precision horse arena design begins long before any ground is broken. It requires systematic assessment of three foundational variables: intended discipline, site characteristics, and regional conditions. Each variable influences every subsequent design decision.

Discipline-Driven Design Philosophy

The quality of arena design directly impacts performance, horse safety, and rider experience. According to Performance Footing’s discipline guide, arena design extends beyond surface selection — it determines long-term health and success across disciplines from dressage to jumping and beyond.

Dressage horses require grip and stability in their surface for precise execution of movements like pirouettes, half-passes, and piaffes. Jumping horses need surfaces firm enough to push off from yet cushioned enough to absorb landing impact. Reining horses require surfaces loose enough to allow controlled sliding stops. These fundamentally different biomechanical demands mean a single generic design cannot serve all disciplines optimally.

Site Assessment Protocol

Performance Footing’s installation methodology begins with comprehensive site analysis including soil testing at multiple depths, drainage pattern mapping, and microclimate assessment. This isn’t optional preparation — it’s the foundation of precision design.

Critical site factors include existing soil composition, natural drainage patterns, sun exposure for outdoor arenas, proximity to water sources for irrigation, and access for construction equipment and material delivery. Locations requiring less leveling and excavation reduce costs while sites in valleys risk flooding regardless of drainage investment.

Designing for Specific Riding Disciplines

Each equestrian discipline places unique demands on horse movement and body mechanics. Tailoring arena design to these requirements enhances performance and reduces injury risk.

Dressage Arena Specifications

Standard competition dressage arenas measure 20 meters by 60 meters (approximately 66 by 197 feet), totaling 12,915 square feet. Small dressage arenas for schooling measure 20 by 40 meters (66 by 131 feet). The longer dimension in full-size arenas allows riders to perform extended movements and tests at higher levels.

The key attributes of ideal dressage design include a flat, uniform surface crucial for precise movement execution. For professionals, even surfaces allow advanced movements requiring perfect balance. For beginners, consistent surfaces build confidence and support correct seat development. Footing depth should remain uniform across the entire arena — typically 2 to 3 inches for dressage work.

Dressage arenas benefit from finer sand particles that provide cushioning and support. The base and subsurface levels make the most significant impact on stability, making correct arena design and structure extremely important for this discipline.

Jumping Arena Requirements

Hunter and jumper arenas require larger dimensions to accommodate full jump courses. Performance Footing recommends 20,000 square feet (100 by 200 feet) for average hunter/jumper arenas, satisfying general requirements for both indoor and outdoor competition.

Indoor jumping arenas require additional height consideration. Performance Footing recommends interior heights of 16 to 18 feet to ensure mounted riders don’t contact the ceiling. Jumpers should plan for the higher end of this range with an additional foot or two for safety margin. Entrance and exit doors should measure 13 to 15 feet tall.

Footing depth for jumping disciplines typically ranges from 3 to 4 inches — deeper than dressage to provide additional shock absorption during landing. The base must withstand significant impact forces while maintaining consistent support across varying weather conditions.

Reining and Western Arena Design

Reining arenas require specialized design that facilitates sliding stops and quick turns while preventing excessive concussion. The surface must provide a firm base with controlled slide capability.

Western disciplines often incorporate a combination of sand and clay to create the right balance between slide and grip required for technical maneuvers. The arena base must be particularly stable to support the lateral forces generated during sliding stops.

Multi-Purpose Arena Considerations

All-purpose arenas typically measure 100 by 200 feet — 34 feet wider than standard dressage dimensions. When designing multi-use facilities, calculate all specifications based on the discipline requiring the greatest dimensions and deepest footing.

Multi-purpose design requires compromise. Consider which disciplines will dominate arena usage when making base and drainage decisions that cannot easily accommodate all requirements equally.

Geographic and Climate Adaptation

What works in one region may fail completely in another. Arena design must account for local soil conditions, weather patterns, and environmental regulations.

Regional Soil Challenges

California’s adobe clay soil expands when wet and contracts when dry — sometimes referred to as “shrink-swell” soils. This ground movement can lift with forces as high as 5,500 pounds per square inch, stronger than concrete foundations. Southern California’s clay particles held together by electrochemical forces create dense layers that prevent drainage and air circulation.

Arizona presents different challenges across elevation zones. Phoenix sits at 1,100 feet while Flagstaff reaches 7,000 feet — a 6,000-foot difference creating completely different construction environments with varying soil types, drainage requirements, weather patterns, and material behaviors.

Performance Footing notes that determining whether soil is sandy, clayey, or loamy is necessary because each type affects drainage differently. Sandy soils drain quickly but may require additional moisture management. Clay soils hold water, potentially leading to pooling and mud. Loamy soils offer balanced drainage but need occasional adjustments.

Climate Impact on Design

Arenas in hot, dry climates look fundamentally different from those in cool, damp environments. According to Performance Footing’s Arizona guide, Phoenix’s extreme heat, Flagstaff’s freeze-thaw cycles, and Tucson’s monsoons each require specialized approaches to base preparation and drainage design.

In cold climates, Penn State Extension research notes that certain salts effectively reduce footing material freezing temperature. However, rubber additives — with their dark color absorbing light and heat — may accelerate thawing but prove unsuitable for hot climate installations where heat retention becomes problematic.

Water availability increasingly influences arena design. According to footing specialist estimates, a 100 by 200 foot outdoor arena may need 2,500 to 4,000 gallons of water daily, climbing to 6,000 gallons during drought conditions. This poses challenges regarding water source capacity, cost sustainability, and potential restrictions during drought periods.

Engineered Drainage Systems

A well-drained arena isn’t luxury — it’s essential for horse health and riding experience. When rainwater cannot properly escape, facilities face canceled rides, unstable footing, and potential horse injury.

Understanding Water Movement

Performance Footing’s drainage guide states that a properly drained 100 by 200 foot arena can clear several inches of rainfall within hours, while poorly drained arenas remain unusable for days or weeks. The goal is simple: water needs a clear path away from the riding surface quickly and efficiently.

Water problems compound over time. When water sits in arenas, it creates conditions for organic decomposition. Sand transforms into bacterial breeding grounds, breaking down faster and creating dust when finally dry. This increases dust control costs, footing replacement frequency, and maintenance expenses.

Grading Requirements

Proper drainage begins with strategic grading. Performance Footing recommends slopes of 1 to 2 percent to direct water away from riding surfaces, potentially implementing crown design in the center to facilitate water flow to the sides.

Slopes steeper than 2 percent cause footing material to migrate downhill over time and may feel uncomfortable for riders and horses. The grading approach should work with property’s natural contours — fighting existing landscape significantly increases costs and complexity.

French Drain Systems

French drains use perforated pipes surrounded by gravel to collect and channel water away from arenas. These systems work effectively for many installations but require proper design and maintenance.

According to Performance Footing’s construction guide, French drains represent one of the most common drainage solutions for outdoor arenas. They consist of trenches containing drainage pipes that allow water to flow outside the arena perimeter.

Geocell Drainage Technology

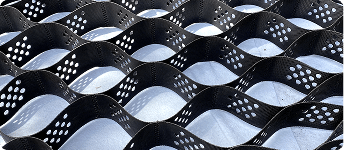

BaseCore geocell technology represents advancement over traditional drainage methods. This honeycomb-structured panel system manages water movement horizontally through arena bases without extensive pipe systems.

Performance Footing documents that a properly installed BaseCore system can move water at rates of 4 to 6 inches per hour — sufficient to handle even heavy downpours. The cellular structure creates pathways for water while simultaneously preventing the lateral material movement that causes traditional bases to fail.

Base Construction and Layering Systems

The arena base determines long-term performance more than any other factor. Premium footing installed on inadequate base underperforms budget footing on properly engineered foundation.

The Five-Layer System

Performance Footing’s construction methodology identifies distinct layers from bottom to top:

Layer 1: Native Subgrade — The existing soil beneath the arena, which must be properly compacted and graded before any construction begins. This layer requires assessment for drainage characteristics and load-bearing capacity.

Layer 2: Geotextile Fabric — Commercial-grade 6oz non-woven fabric laid across the entire arena footprint. This fabric serves multiple purposes: preventing weed growth, separating base materials from native soil, and enhancing overall drainage efficiency. Performance Footing offers geotextile in 12.5 by 360 feet rolls, providing coverage for most arena projects.

Layer 3: Geocell Foundation — Three-dimensional honeycomb structures made from geosynthetic materials that stabilize and reinforce the ground. BaseCore geocells distribute weight across greater area, prevent material shifting, create additional strength, prevent ground sinkage, and promote drainage.

Layer 4: Aggregate Base — Riding arena bases typically comprise 4 to 6 inches of compacted, well-graded materials. Base material such as crushed stone is introduced and compacted by 10-ton roller. The base must be thoroughly compressed to prevent uneven surfaces.

Layer 5: Footing Surface — The riding surface combining sand with appropriate additives for the intended discipline. This layer receives the most attention but depends entirely on the foundation beneath it.

Traditional vs. Geocell Base Economics

Traditional arena base construction follows expensive formulas where more depth equals more stability. A 100 by 200 foot arena typically requires 6 to 8 inches of compacted base material — approximately 370 cubic yards of aggregate. At $30 per yard delivered, materials alone cost $11,100 before installation labor, equipment rental, and compaction time pushes total investment to $20,000 or more for a base that might last 10-15 years.

Performance Footing’s BaseCore approach requires only 3 to 4 inches of aggregate when confined within geocell structure — 185 cubic yards or less, cutting material costs by more than half. Most BaseCore installations cost 40-60% less than traditional bases while delivering superior performance.

BaseCore Specifications

Performance Footing offers BaseCore in multiple depths for different applications:

- 2 inches: Ideal for grooming paths, stall floors, and wheelbarrow access

- 3 inches: Great for arenas, runs, parking, and private driveways

- 4-6+ inches: Best for slow-draining arenas, muddy paddocks, erosion control, and slope retention

BaseCore HD features cells approximately 50% smaller than standard geocells, creating substantially more reinforcement points throughout installation. This smaller cell design provides extraordinary stability while preventing horse hooves from becoming trapped — a safety consideration standard larger-cell geocells cannot match.

Alternative Base Approaches

For facilities where geocell systems aren’t appropriate, traditional layered construction remains viable:

Compacted Base Method — Most affordable approach using screenings or road base wetted down and mechanically compacted. Requires 6-8 inches of material and regular maintenance.

Free-Draining Base — Crushed rock mixed with synthetic material facilitating better drainage. Some owners add rubberized mats or subsurface systems improving both drainage and dust control.

Subsurface Moisture Management — Advanced installations may include automated irrigation and drainage systems that maintain optimal moisture levels from below the footing surface.

Material Selection for Base and Drainage

Choosing appropriate materials requires understanding how each component contributes to overall system performance.

Aggregate Selection

Large, angular crushed rock promotes water flow through inherent voids, while smaller stone dust fills gaps preventing soil migration and maintaining overall stability. Performance Footing recommends consulting with experienced arena builders for optimal aggregate blends based on specific soil type and climate conditions.

The lower section of base consists of permeable composition of rocks and gravel. Quality matters — poor aggregate selection leads to premature failure regardless of design quality.

Geotextile Types

Two geotextile types serve different purposes:

Woven Geotextiles — Similar to weed cloth, rarely used in arena construction process. If used, placed on compacted sub-base prior to adding rock layer.

Non-Woven Geotextiles — The preferred choice for arena construction. When used with BaseCore geocell, non-woven geotextile on compacted sub-base provides drainage capability and stabilization for the entire arena. This material also works in paddocks and turnouts to reduce muddy areas.

Sand Specifications

While this guide focuses on design rather than footing, base sand selection impacts overall system performance. Performance Footing provides sand analysis reports with specific sieve measurements for indoor and outdoor applications. Their outdoor specification targets precise particle distribution: 0% retention at #18 mesh, 7.40% at #35 mesh, 48.50% at #60 mesh, 34.00% at #100 mesh, 7.40% at #140 mesh, and 1.50% at #270 mesh.

Penn State Extension research confirms that if more than 5% of material passes a #200 sieve screen, footing tends toward excessive dustiness. Keeping fines below this threshold reduces respiratory risks for horses and riders.

Project Planning and Implementation Timeline

Successful arena construction follows documented sequences that experienced builders understand and novice builders often skip.

Phase 1: Assessment and Design (2-4 weeks)

Conduct comprehensive site analysis including soil testing at multiple depths. Map existing drainage patterns. Assess sun exposure, wind patterns, and microclimate factors. Determine discipline requirements and arena dimensions. Obtain necessary permits.

Phase 2: Site Preparation (1-2 weeks)

Clear vegetation and debris. Excavate to appropriate depth — typically 6-12 inches depending on soil conditions and base system selected. Address any soft spots or problem areas in subsoil. Install perimeter drainage if required.

Phase 3: Base Installation (1-2 weeks)

Install geotextile fabric across prepared subgrade. Deploy geocell panels or begin traditional aggregate installation. Fill geocells with appropriate aggregate and compact. For traditional bases, install and compact each 3-4 inch layer separately before adding next layer.

Phase 4: Drainage Completion (3-5 days)

Verify proper grading throughout arena. Test drainage performance before footing installation. Make adjustments as needed — problems are far easier to correct before footing covers the base.

Phase 5: Footing Installation (3-5 days)

Install sand to appropriate depth for discipline. Add footing additives if specified. Drag and groom surface to establish even distribution. Allow settling period before heavy use.

Seasonal Considerations

Installation timing affects outcomes. Southern California projects ideally occur in late spring after winter rains but before summer heat. Northern regions work best in early fall when soils are dry but temperatures remain moderate.

Spring thaws can overwhelm even well-designed systems if outlets remain blocked with winter debris. Plan annual maintenance schedules around seasonal transitions.

Conclusion

The 10-15 year reconstruction cycle plaguing traditional arena construction stems directly from imprecise design — generic approaches that ignore discipline requirements, geographic realities, and engineering principles for proper layering and drainage. Performance Footing’s systematic methodology addresses each variable: discipline-specific dimensions and footing depths, geographic adaptation for soil and climate conditions, engineered drainage through proper grading and geocell technology, and layered construction that delivers 75+ year base system lifespans.

Your next step: Contact Performance Footing at 877-835-0878 for a free consultation including site assessment recommendations, discipline-specific design guidance, and material specifications for your geographic region.

FAQ Section

What arena size do I need for dressage competition?

Standard FEI competition dressage arenas measure 20 by 60 meters (66 by 197 feet). Small schooling arenas measure 20 by 40 meters. Indoor arenas require 16-18 foot ceiling heights.

How does soil type affect arena base design?

Clay soils require enhanced drainage systems and may need geocell stabilization. Sandy soils drain quickly but may lack stability. Performance Footing recommends soil testing before any design decisions.

What slope is required for proper arena drainage?

Performance Footing recommends 1-2% grade for water runoff. Slopes exceeding 2% cause footing migration and rider discomfort. Crown designs direct water from center to perimeter.

How long does a properly engineered arena base last?

Traditional compacted bases require reconstruction every 10-15 years. BaseCore geocell systems have documented 75+ year expected lifespans with proper installation and minimal maintenance.

Can I install arena base systems myself?

BaseCore geocell installation requires no formal training — two or more people with basic tools can complete installation following Performance Footing’s guide. However, professional installation ensures proper specifications and includes product discounts.