A therapeutic riding center in Michigan transformed their operation from a six-month seasonal program to year-round service after installing an all-weather arena system. Previously, spring mud season and winter freeze-thaw cycles forced them to cancel lessons for half the year. According to Performance Footing’s documented case study from 2024, the facility now serves clients twelve months annually, doubling their community impact. This transformation illustrates what’s possible when arena construction addresses seasonal conditions from the foundation up.

This guide reveals how to plan and build all-weather arenas, paddocks, and access areas that perform consistently through freeze-thaw cycles, excessive rain, and drought conditions.

What All-Weather Arena Construction Means Through Real-World Implementation

An all-weather arena is more than marketing terminology—it describes a specifically engineered riding surface that maintains consistent performance regardless of seasonal conditions. The concept gained practical definition through facilities that documented their construction methods and measured results.

Stephens College in Missouri provides a clear example. Celebrating their 100-year equestrian program anniversary in 2026, the institution invested in BaseCore HD geocell technology for their arena base reconstruction. According to Performance Footing’s November 2025 technical documentation, Stephens College explicitly planned for the next century of equestrian excellence. Their commitment reflects a growing industry understanding that 80% of arena problems originate from inadequate base construction.

The college’s implementation addressed three primary weather challenges: Missouri’s freeze-thaw cycles that can damage traditional bases, spring flooding from seasonal rainfall, and summer heat that dries out conventional footing. By engineering solutions for each challenge into the base layer, they created a truly all-weather surface.

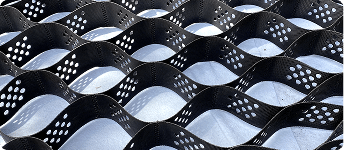

Performance Footing’s technical specifications, published in 2024, document how BaseCore HD’s cellular confinement system works. The honeycomb structure features 7.2-inch by 6.0-inch cells—the smallest dimensions available in the market. This design creates equivalent strength to 12 inches of traditional aggregate using only 6 inches of material when properly installed. The engineering principle relies on lateral confinement of aggregate particles within the cells, preventing displacement under load while maintaining vertical drainage through engineered perforations.

How Performance Footing Facilities Achieved All-Weather Results

Understanding how successful facilities engineered their all-weather solutions provides a practical roadmap for new construction. Multiple documented installations reveal consistent approaches adapted to regional conditions.

Tools and Platform Selection

Performance Footing installations typically incorporate three integrated components. BaseCore HD geocell panels form the structural base, creating cellular confinement that stabilizes aggregate while maintaining drainage pathways. PF Geotextile Fabric (commercial-grade 6oz non-woven) prevents soil migration while allowing water percolation. Discipline-specific footing additives like FoamFooting, EcoStride, or Noviun address surface performance requirements.

The sand selection process uses specific sieve analysis to match particle distribution to arena type. Performance Footing’s technical documentation specifies target distributions for indoor versus outdoor arenas. For outdoor applications, the target shows 7.40% retained at 35 mesh, 48.50% at 60 mesh, 34.00% at 100 mesh, 7.40% at 140 mesh, and 1.50% at 270 mesh. Indoor specifications adjust these percentages to account for different moisture and dust management requirements.

Implementation Timeline

A Colorado facility’s installation demonstrates typical project timelines. According to Performance Footing’s September 2025 case study, the facility saved $25,000 in site preparation costs by using BaseCore instead of traditional base construction on their hillside arena. The project proceeded in distinct phases.

Site preparation consumed the first week, including vegetation removal, rough grading to establish proper drainage slopes, and compaction of native soil to 95% density. The second week focused on geotextile fabric installation and BaseCore panel deployment. Unlike traditional construction requiring weeks of aggregate delivery, spreading, and compaction, BaseCore panels unfold quickly across prepared subgrade. The final week addressed aggregate filling of cells, final grading, and footing installation.

Traditional arena construction requires different timelines—often stretching to months when weather delays interrupt aggregate compaction processes.

Team Structure and Resources

The Oregon dressage facility that achieved 68% fewer canceled lessons used a three-person installation team. Performance Footing’s documentation notes that no specialized training is required—barn crews can position panels while aggregate delivery occurs. The lightweight panel design eliminates heavy equipment requirements for base installation, though standard skid steers and compactors remain necessary for site preparation and aggregate work.

Challenges Encountered

The Oregon facility struggled with consistent flooding before their BaseCore installation, regularly forcing lesson cancellations and creating dangerous riding conditions. Their traditional drainage approach had failed despite significant investment in French drain systems. The challenge emerged from clay-heavy native soils that prevented proper water percolation regardless of surface drainage provisions.

BaseCore’s cellular structure solved this by creating pathways for water to move laterally through the arena base without requiring extensive pipe systems. The honeycomb panels manage water movement horizontally through the base, eliminating standing water problems that plagued traditional approaches.

Metrics Tracked

Facilities tracked several performance indicators: days rideable after rainfall events, annual maintenance costs, lesson cancellation rates, and footing replacement intervals. The Oregon facility measured a specific outcome—68% reduction in weather-related cancellations. A therapeutic riding center tracked $12,000 in annual maintenance savings compared to their previous arena system.

Measurable Outcomes and ROI from All-Weather Construction

Documented installations provide specific before-and-after metrics demonstrating all-weather arena value.

Weather Event Performance

A hunter/jumper arena in Florida using BaseCore withstood a 4-inch rainfall event and was rideable within 3 hours, according to Performance Footing’s November 2025 documentation. This compares to traditional bases in similar conditions requiring 24-48 hours or more to become usable.

After Hurricane Harvey deposited 40 inches of rain on Houston-area arenas in 2017, facilities with BaseCore bases were riding within 24 hours of the storm passing. Traditional bases in the same area remained unusable for weeks, with many requiring complete reconstruction.

Freeze-Thaw Resistance

Facilities in Minnesota and Alberta report zero freeze-thaw damage after decades of BaseCore use, while neighboring arenas require complete reconstruction every 10-15 years. Performance Footing’s September 2025 technical documentation explains this performance: water drainage through the cellular structure prevents ice lens formation that causes frost heaving.

Ice lens formation occurs when certain soils exposed to freezing temperatures have access to liquid water—capillary action draws water toward the freezing front, where it freezes and accumulates into layered ice bands. These ice lenses expand and lift soil, causing structural damage known as frost heave. BaseCore’s drainage channels prevent water accumulation that enables ice lens formation.

Cost Analysis

A standard 60×120 foot arena using BaseCore HD requires approximately $7,000-8,500 in base materials, delivering a premium system lasting 75+ years with minimal maintenance. Traditional base construction requires $10,000-15,000 in aggregate alone, plus drainage systems costing another $5,000-10,000.

The Colorado facility’s $25,000 savings in site preparation alone exceeded their entire BaseCore investment. When facilities calculate lifecycle costs including reconstruction intervals, the economics shift dramatically. Traditional bases requiring replacement every 10-15 years accumulate $40,000-80,000 in reconstruction costs over 20 years—costs BaseCore installations avoid entirely.

Trade-offs and Considerations

Initial material costs for engineered all-weather systems exceed basic construction approaches. A budget arena using compacted native soil, minimal aggregate, and sand-only footing might cost $1-2 per square foot. Mid-range systems incorporating BaseCore run $3-5 per square foot. Premium installations with BaseCore HD and advanced footing additives reach $5-8.50 per square foot.

However, maintenance requirements differ substantially. Budget arenas need frequent re-grading, drainage repairs, and footing replacement. Facilities report minimal ongoing maintenance with BaseCore systems—no reconstruction needed for 75+ years and dramatically reduced watering requirements.

Analyzing Regional Approaches to Seasonal Challenges

Different climates present distinct challenges requiring adapted solutions. Publicly documented installations reveal how facilities addressed regional conditions.

Wet Climate Solutions: Pacific Northwest

The Oregon dressage facility faced persistent rainfall exceeding 30 inches annually. Their BaseCore installation demonstrated that geocell arenas returned to rideable condition 65% faster than traditional drainage systems. The key adaptation involved integrating perimeter drainage collection with the BaseCore cellular network, creating redundant water management pathways.

Extreme Weather: Gulf Coast

Florida and Texas facilities face both intense storm events and extended dry periods. The Houston installations that survived Hurricane Harvey demonstrated BaseCore’s capacity to handle massive water volumes—the cellular structure creates defined drainage channels without erosion or displacement that destroys traditional bases.

Freeze-Thaw Regions: Upper Midwest and Canada

The Minnesota and Alberta facilities with zero freeze-thaw damage over decades represent the longest-documented BaseCore installations in severe winter climates. Their success validates the engineering principle that proper drainage prevents ice lens formation.

Drought Conditions: California and Southwest

California horse arena owners face what Performance Footing’s October 2025 documentation describes as “a perfect storm of challenges.” Water restrictions can fine agencies up to $10,000 daily for non-compliance. Adobe clay soils expand 30% when wet then crack when dry. Some facilities spend over $50,000 annually on arena watering.

Performance Footing’s California-specific solutions reduce water usage by 65% through moisture-retaining footing additives like Noviun (coconut coir fiber) and ArenaGreen (waterless footing). These materials maintain ideal moisture levels longer after watering, reducing frequency while preventing drought cracking.

Practical Implementation Guide for All-Weather Construction

Successful installations follow documented methodologies that address seasonal conditions at each construction phase.

Phase 1: Site Assessment and Planning

Before breaking ground, evaluate your site’s specific seasonal challenges. Document existing drainage patterns during rainfall events. Note freeze-thaw behavior through at least one winter cycle. Identify native soil composition—clay-heavy soils require different approaches than sandy or loamy soils.

Performance Footing recommends professional soil analysis to determine permeability rates and compaction characteristics. This $200-500 investment prevents thousands in failed construction attempts.

Establish proper grades during planning. For outdoor arenas, implement a 1-2% crown in the center enabling water to flow outward, preventing puddles and uneven footing. The first critical principle involves grading the arena to work with your property’s natural contours rather than fighting them.

Phase 2: Site Preparation

Site preparation follows a specific sequence regardless of final system selection.

Remove all existing surface material and excavate to proper depth—typically 6-12 inches depending on your base system. Address soft spots in subsoil before proceeding. Install perimeter drainage if site assessment indicated water collection issues.

Compact native soil to 95% density using appropriate equipment. This step is non-negotiable—soft or uneven subgrade causes every layer above it to fail. Surface grading creates the 1-2% crown or slope for surface drainage.

Phase 3: Base Layer Installation

Spread geotextile fabric across the prepared subgrade. This silent guardian acts as a barrier, stopping soil migration while allowing water percolation. Performance Footing offers commercial-grade 6oz non-woven fabric in 12.5×360 feet rolls.

Deploy BaseCore or BaseCore HD panels according to your arena dimensions. The panels unfold and connect without specialized tools. Cut panels as needed to fit around drainage pipes or other obstacles.

Fill cells with appropriate aggregate—typically 3/8-inch minus crushed rock. Only 4 inches of fill is required compared to 6-12 inches for traditional bases. Compact material within cells and verify grades throughout installation.

Phase 4: Footing Installation

Add final base layer of stone dust or fine crushed stone. Grade to final specifications and compact thoroughly. Test drainage with water before adding riding surface—this verification step catches problems while correction remains practical.

Install footing appropriate to your discipline and climate. Dressage arenas typically require 2.5-3 inches for firm, consistent contact. Jumping arenas need 3-4 inches for adequate cushioning during landing. Reining and barrel racing demand 4-6 inches to accommodate sliding stops and high-speed turns.

Phase 5: Extending All-Weather Design to Paddocks and Access Areas

The arena represents only one component of year-round usability. Paddocks, turnout areas, and access lanes require equal attention to seasonal conditions.

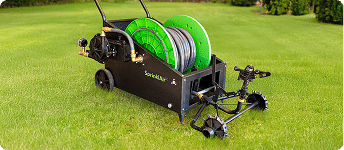

PaveCore grid systems address paddock mud control using similar engineering principles. The interlocking panels create stable, durable surfaces bearing heavy traffic while ensuring rapid water runoff. A private horse owner documented immediate improvement in mud management after installing PaveCore—horses navigated paddocks without sinking into mud.

High-traffic areas around gates, water troughs, and feeding stations benefit most from PaveCore installation. These zones see concentrated hoof traffic that destroys unimproved surfaces during wet conditions.

Access lanes connecting arenas to barns and pastures often become impassable during spring thaw. BaseCore or PaveCore installation in these critical pathways maintains year-round accessibility. The investment typically costs less than annual repair of rutted, muddy lanes.

Seasonal Maintenance Protocols

Even properly constructed all-weather arenas require seasonal attention to maintain optimal performance.

Spring Protocols

Inspect BaseCore and PaveCore installations for any winter damage requiring attention. Clear winter debris from French drains and culverts to prepare for spring rains. Add a thin layer of appropriate material to BaseCore installations to refresh surfaces after winter use.

Spring thaws can overwhelm even well-designed systems if outlets are blocked. A five-minute perimeter walk prevents minor issues from becoming major problems.

Summer Protocols

Dust management becomes the primary focus during dry months. Moisture-retaining additives like FoamFooting or Noviun reduce watering frequency while maintaining surface quality. Strategic watering of pasture areas helps maintain vegetation that reduces overall erosion.

For arenas without waterless footing, establish consistent watering schedules. The typical outdoor arena requires more than 2,500 gallons of water daily under standard conditions—more in arid climates.

Fall Protocols

Prepare drainage systems for increased rainfall. Clear outlets, check perimeter drainage, and verify water flows away from arenas rather than pooling. Consider adding footing depth before winter if levels have decreased through summer use.

Winter Protocols

In freeze-thaw regions, maintain drainage outlet clearance to prevent ice damming. Avoid heavy arena use when footing is frozen—even all-weather surfaces can sustain damage from hooves on frozen material. Monitor for any frost heave indicators, though properly installed BaseCore systems resist this damage.

Conclusion: Building for Every Season

The Michigan therapeutic riding center that transformed from seasonal to year-round operation demonstrates what thoughtful all-weather construction achieves. Their investment in proper base engineering—addressing freeze-thaw, drainage, and accessibility throughout the facility—doubled their community service capacity.

The documented metrics from facilities across climate zones confirm consistent outcomes. BaseCore installations show 65% faster return to rideable conditions after rainfall. Freeze-thaw damage drops to zero in properly installed systems. Maintenance costs decrease by $12,000 or more annually. Facilities remain operational 30+ additional days per year.

Your next step is straightforward: assess your site’s specific seasonal challenges and match solutions to those conditions. Contact Performance Footing at 877-835-0878 for a consultation addressing your soil type, climate, and riding discipline requirements.

Frequently Asked Questions

How does BaseCore prevent freeze-thaw damage in arenas?

BaseCore’s cellular structure drains water before freezing occurs, preventing ice lens formation that causes frost heaving. Facilities in Minnesota and Alberta report zero freeze-thaw damage after decades of use.

What makes an arena truly “all-weather” versus standard construction?

All-weather arenas incorporate engineered drainage at the base layer, climate-appropriate footing materials, and proper grading. Standard construction often addresses only surface drainage, failing during extreme conditions.

How quickly can I ride after heavy rain with BaseCore installed?

Documented installations show 3-hour return to rideable conditions after 4-inch rainfall events. A Houston facility was rideable within 24 hours after Hurricane Harvey’s 40 inches of rain.

Should paddocks and access areas use the same construction as arenas?

PaveCore grid systems address paddock and access lane needs using similar principles but different configurations. These areas require stable surfaces handling hoof traffic without arena-specific footing depth requirements.

How do drought conditions affect all-weather arena maintenance?

Footing additives like Noviun and ArenaGreen retain moisture 65% longer than sand alone, reducing watering frequency. California facilities report dramatic water savings while maintaining consistent surface performance.