Every arena problem you’ve experienced likely started six inches below where you think it did. According to Performance Footing’s drainage-first arena guide, when horses sink into deep spots after rain, when your formerly level arena develops mysterious dips and valleys, when puddles form despite expensive footing upgrades—these issues originate in the base, not the surface. Industry research confirms that arena problems usually start at the sub-base and the base, and putting brand new footing on the wrong arena base creates long-term problems including material migration, stones surfacing through footing, and chronic drainage failures. This guide examines why surface grooming can never fix base-level failures and presents three distinct solutions: hiring Performance Footing’s professional team, installing BaseCore geocell technology yourself, or learning to properly layer and construct your arena from the ground up.

The Anatomy of Arena Failure: Why Grooming Falls Short

Understanding the Multi-Layer System

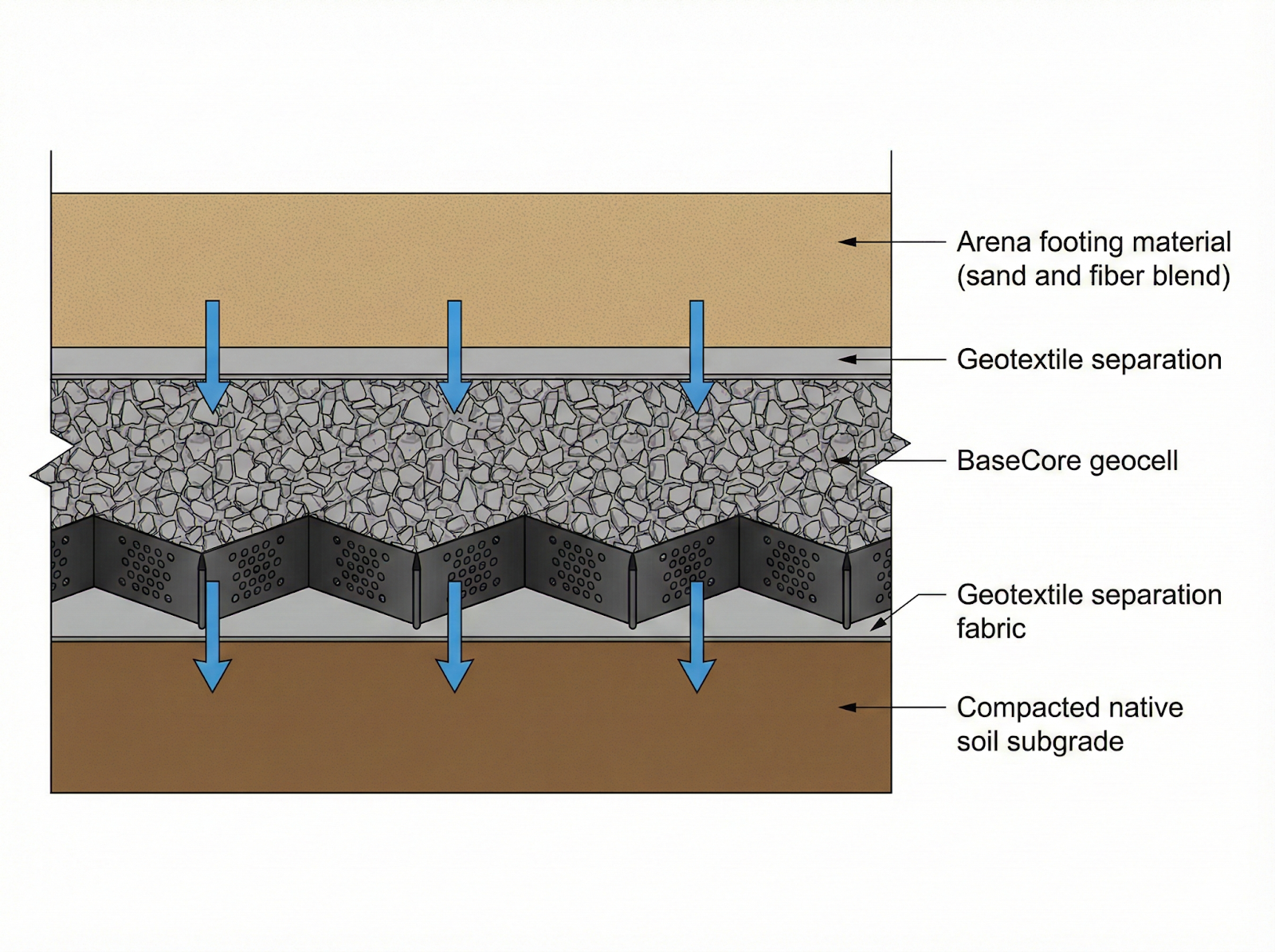

A successful arena is never just a surface—it’s a composite structure where each layer serves a critical function. Performance Footing’s arena layers guide identifies the essential components:

Native Soil Subgrade: The correctly graded and compacted natural soil forming the ultimate foundation.

Drainage Layer: Systems that direct water away from the riding surface, whether French drains, graded slopes, or geocell technology.

Base Layer: Typically 4-6 inches of compacted angular stones that create a firm, stable platform.

Separation Layer: Geotextile fabric preventing material migration between layers.

Footing Surface: The riding surface material—sand, fiber blends, or specialized footing products—typically 2-4 inches deep.

When any layer below the footing fails, no amount of surface work can create lasting improvement. As Performance Footing’s arena construction guide states, an arena is only as good as and will only last as long as its base.

The Physics of Base Failure

Traditional arena bases rely entirely on massive amounts of crushed stone to achieve stability, according to Performance Footing documentation, often requiring 6-12 inches of expensive aggregate that still shifts, settles, and fails over time.

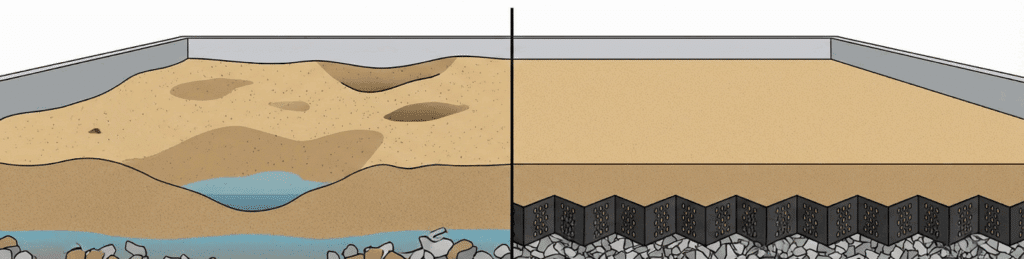

The failure mechanism follows predictable patterns. Loose aggregate migrates laterally under repeated hoof impact, creating voids that become deep spots. Water infiltrates these voids, accelerating settling and preventing proper drainage. The weight of saturated material causes additional settling, permanently altering the arena’s level surface.

Performance Footing’s drainage guide explains: Think of it like the difference between loose marbles in a box versus marbles secured in individual compartments. The loose marbles shift and settle with any movement, creating voids and high spots. Traditional arena bases work the same way—without cellular confinement, aggregate inevitably moves.

Why Grooming Creates Only Temporary Relief

Arena grooming equipment—harrows, drags, and groomers—is designed to work within the footing layer. Industry best practices indicate grooming accomplishes specific surface-level tasks: leveling out divots and shallow spots, remixing separated particles and additives, breaking up compacted surface areas, and redistributing moisture.

None of these functions address what happens below the footing. The Horse magazine’s arena troubleshooting guide notes that if you can see base or stones coming up through the surface, the only way to fully investigate and confirm the nature of the problem is to remove the footing entirely.

This explains why deep spots return within days or weeks of grooming. The surface temporarily levels, but the underlying void remains. Each subsequent grooming session moves footing material into the depression, creating the illusion of repair while actually depleting footing depth in surrounding areas.

Recognizing Base Problems vs. Surface Problems

Understanding whether your arena suffers from base failure or simple surface issues determines whether grooming can help or simply wastes time and money.

Signs of Base-Level Failure:

- Deep spots that return within days of grooming, regardless of approach

- Puddles that persist hours or days after rain stops

- Stones or base material migrating up through footing

- Soft, boggy areas that never fully firm up

- Uneven surface despite consistent dragging patterns

- Footing depth that varies dramatically across the arena

Signs of Surface-Level Issues (Grooming Can Help):

- Temporary compaction from traffic patterns

- Rail ruts and jump approach divots

- Dust accumulation in dry conditions

- Uneven moisture distribution

- Minor particle separation

Performance Footing recommends a simple diagnostic: probe the footing with a measuring stick at multiple locations. If you cannot reach the base, or if you find 2 inches of footing in one area and 5 inches in another, you have base-level problems that surface work cannot address.

Solution 1: Hire Performance Footing’s Professional Team

When Professional Installation Makes Sense

For facility owners facing significant base failure, working with substantial renovation budgets, limited on time or equipment, or desiring guaranteed results, Performance Footing’s professional installation services deliver expertise that eliminates guesswork and prevents costly mistakes.

Performance Footing’s cost analysis indicates that professional installation typically costs less than the mistakes and rework associated with DIY attempts. This counterintuitive reality reflects the specialized knowledge, equipment, and efficiency that experienced crews bring to arena construction.

What Professional Installation Includes

Performance Footing provides comprehensive arena construction services encompassing every phase of the project:

Site Evaluation and Ground Preparation: The team assesses soil conditions and topography to determine the best approach for leveling, compaction, and drainage. This evaluation prevents the common mistake of building on unsuitable ground without proper modification.

Base Stabilization and Drainage Installation: Using BaseCore geocells, they create a stable and well-draining foundation that prevents shifting, waterlogging, and uneven footing. This addresses the root cause of most arena failures.

Custom Arena Design and Build: Performance Footing specializes in designing and constructing bespoke indoor and outdoor arenas, all-weather gallops, lunge pens, and stable yards tailored to specific disciplines and site conditions.

Footing Selection and Installation: Beyond base work, their team coordinates complete footing installation, ensuring all components work together for optimal performance.

The Professional Advantage

Performance Footing’s installation service delivers several documented advantages according to their pricing analysis:

Precision and Efficiency: Experienced crews complete installations faster and more accurately than first-time installers, reducing labor costs and ensuring optimal results.

Proper Equipment: Professional installation includes specialized compaction equipment and grading tools that most facilities don’t own, eliminating rental costs and ensuring proper base density.

Guaranteed Results: When Performance Footing installs your arena, you receive assurance that the job is done correctly the first time, preventing costly mistakes that could require expensive corrections.

Comprehensive Solutions: Their team coordinates complete arena construction including footing installation, ensuring all components work together perfectly.

Professional Installation Investment

Performance Footing offers a 10% product discount when choosing their professional installation, often offsetting much of the installation cost. For facilities that value time and certainty over hands-on involvement, this represents the most straightforward path from problem arena to professional-quality riding surface.

Contact Performance Footing at (877) 835-0878 for a professional consultation that includes soil analysis, drainage assessment, and discipline-specific recommendations tailored to your facility.

Solution 2: Install BaseCore Geocell Technology Yourself

Why BaseCore Solves What Grooming Cannot

BaseCore geocell technology addresses the fundamental physics of base failure. Rather than relying on aggregate depth alone—the approach that created your current problems—BaseCore’s honeycomb structure confines and stabilizes aggregate within individual cells.

Performance Footing’s technical documentation explains: The three-dimensional structure acts like rebar in concrete, providing tensile strength that flat aggregate layers can’t achieve. When properly installed with angular aggregate filling each cell, BaseCore creates a base that’s actually stronger than traditional deep stone bases while using 50-70% less material.

This cellular confinement prevents the lateral movement that causes traditional bases to fail, while creating consistent drainage channels that keep your arena rideable even after heavy rain.

BaseCore Specifications for Arena Renovation

Performance Footing recommends specific BaseCore configurations for arena applications:

3-inch BaseCore HD: Great for arenas, runs, parking areas, and private driveways. The HD version features cell sizes almost 50% smaller than standard geocell products, providing superior strength with less fill material.

4-6 inch BaseCore HD: Best for slow-draining arenas, areas with poor native soil, erosion control, and slope retention requiring heavy-duty reinforcement.

The BaseCore HD cell dimensions measure 7.2 inches by 6.0 inches—the smallest in the market—creating tighter cellular confinement that prevents aggregate migration while remaining safe for horse hooves.

DIY Installation Process

Performance Footing’s installation guides outline a straightforward process that two or more people can complete without specialists or heavy equipment:

Step 1: Assess and Excavate Remove existing failed footing and base material. For complete renovation, excavate to stable native soil—typically 6-12 inches depending on existing conditions. Compact native soil thoroughly using a vibrating plate compactor.

Step 2: Establish Proper Grade Create either a slight crown in the center (1-2% grade) or angle the entire arena surface to promote water runoff. Some locations with particularly poor drainage benefit from adding a 4-inch drainage rock layer over compacted native soil.

Step 3: Install Geotextile Fabric Lay commercial-grade 6oz non-woven geotextile fabric across the entire arena footprint. Performance Footing offers 12.5×360 feet rolls at $899. Overlap seams by 8-12 inches to prevent soil migration.

Step 4: Deploy BaseCore Panels Expand BaseCore panels accordion-style to full dimensions. The 3-inch BaseCore HD panels come in 10×12 feet sections at $149 each. Position on geotextile and secure adjacent panels using BaseClips connection system. Anchor to subgrade using BaseCaps.

Step 5: Fill and Compact Fill expanded cells with 3/8-inch minus crushed rock. Performance Footing specifies only 4 inches of aggregate needed—compared to 6-12 inches for traditional bases. Use a vibrating plate compactor to settle material within and above cells.

Step 6: Add Footing With BaseCore base complete, add your chosen arena footing material. The permanent, stable base supports any footing type and eliminates the chronic problems that prompted renovation.

Material Investment for DIY

For a standard 60×120 foot arena, Performance Footing’s pricing guide indicates:

- BaseCore HD panels (approximately 60 panels): $8,940

- Geotextile fabric: $899

- Aggregate fill (4 inches of 3/8″ minus): $2,000-3,500

- Total base investment: $11,839-13,339

Compare this to traditional base reconstruction requiring $10,000-15,000 in aggregate alone, plus $5,000-10,000 for French drain systems, plus professional installation labor. BaseCore’s DIY approach delivers superior performance at comparable or lower cost while eliminating the failure modes that caused original problems.

Solution 3: Learn Proper Arena Construction Principles

For Those Building New or Starting Over

Whether you’re constructing a new arena or undertaking complete reconstruction, understanding proper layering principles prevents the problems that no amount of future grooming can fix.

Performance Footing’s ultimate arena construction guide emphasizes: When it comes to ensuring the longevity and performance of your horse arena, establishing a solid base is paramount. This foundational layer directly impacts the lifespan and effectiveness of the arena footing. Think of it as the backbone of your facility, providing unwavering support for everything above it.

The Seven Principles of Lasting Arena Construction

Principle 1: Site Selection Matters

Choose locations with natural drainage away from buildings and paddocks. Placing your arena on higher ground naturally improves drainage. Consider sun exposure to help dry the surface after rain. Avoid low-lying areas where water naturally collects.

Principle 2: Proper Subgrade Preparation

The native soil subgrade must be correctly graded and compacted before any materials are added. Performance Footing’s tips for arena base construction emphasize: Start by compacting the sub-base layer, and continue compacting after every additional layer of material. Use heavy machinery like a roller to ensure each layer is packed down properly.

Test compaction by driving a metal rod into the prepared subgrade at multiple points. Consistent resistance indicates proper compaction. Soft spots need addressing before proceeding.

Principle 3: Establish Drainage Before Building Up

Performance Footing’s drainage guide states: Your horse arena’s performance largely hinges on how well excess water is directed away from both the footing and the base layers.

Key drainage principles include:

- Grading and slope: Implement a 1-2% crown in the center enabling water to flow outward

- Perimeter drains: Integrate systems around the arena’s perimeter to collect and direct water away

- Retaining boards: Install edge boards to keep footing contained and prevent migration into drainage systems

Principle 4: Use Quality Base Materials

Not all base materials are created equal. Performance Footing’s construction guide specifies: Arena bases are made up of different types of stone and gravel. The types of crushed rocks used affect how hard your base is.

The aggregate stone layer should use primarily sub-angular stones ranging from 1/8 inch to 1 inch. This layer typically measures 2-3 inches deep when building traditionally, or fills BaseCore cells when using geocell technology. The base needs thorough compression to prevent uneven surfaces.

Principle 5: Separate Layers Properly

Geotextile membranes separate your base layer from your sand and arena footing, according to Performance Footing’s construction guide. Non-woven geotextile allows for drainage while providing stabilization and preventing material mixing.

This separation layer prevents two critical failure modes: base material mixing with arena sand, and footing particles migrating down into base aggregate. Both scenarios degrade performance and require complete reconstruction to address.

Principle 6: Consider Geocell Reinforcement

Performance Footing’s base construction tips explain: Without geocell reinforcement, your arena base may deteriorate over time, causing dips, ruts, and uneven surfaces. Geocells not only keep your arena stable but also improve drainage, minimizing the risk of erosion.

BaseCore’s honeycomb-shaped cells distribute weight evenly across the surface, reinforcing the base and preventing shifting or settling. This addresses the fundamental weakness of traditional aggregate-only bases.

Principle 7: Match Footing to Discipline and Climate

Penn State Extension’s arena footing research confirms: A successful arena surface is no better than the underlying foundation of base and sub-base it rests upon. But footing selection matters too.

Performance Footing offers discipline-specific guidance:

- Dressage arenas typically need 2-3 inches of footing depth

- Jumping arenas benefit from 3-4 inches for landing absorption

- Multi-purpose arenas balance requirements across disciplines

Sand deeper than 6 inches stresses horse tendons according to Penn State research. Start with about 2 inches and add in 1/2-inch increments as necessary.

Common Construction Mistakes to Avoid

Mistake 1: Skipping Compaction Each layer requires thorough compaction before adding the next. Rushing this step guarantees settling problems that manifest as deep spots within months.

Mistake 2: Wrong Aggregate Type Round stones migrate and shift. Angular, crushed aggregate interlocks for stability. The “minus” designation (3/8″ minus) indicates presence of fines that improve compaction.

Mistake 3: Inadequate Drainage Planning Water management must be designed before construction begins. Retrofitting drainage into a completed arena costs significantly more and delivers inferior results.

Mistake 4: Mixing Incompatible Materials Clay-heavy native soil mixing with arena sand destroys footing performance. Proper separation layers prevent this contamination.

Mistake 5: Insufficient Base Depth Traditional bases need 4-6 inches minimum. Cutting this depth saves money initially but guarantees premature failure. BaseCore technology allows reduced depth while maintaining performance.

Making Your Decision: Which Path Forward?

Choose Professional Installation If:

- Your time is more valuable than hands-on involvement

- You want guaranteed results without learning curve

- Budget allows for comprehensive service

- The project scope exceeds DIY comfort level

- You prefer ongoing support relationship with experts

Performance Footing’s professional team manages every phase from site evaluation through final footing installation, with documented results including arenas that return to rideable condition 65% faster after storms compared to traditional construction.

Choose DIY BaseCore Installation If:

- You have basic construction skills and equipment access

- Budget prioritizes materials over labor

- You enjoy hands-on projects and learning

- Timeline allows for self-paced work

- You want maximum control over the process

BaseCore’s design specifically accommodates DIY installation. Performance Footing states that two or more people with simple tools can complete installation without formal training, following their straightforward 6-step process.

Choose Ground-Up Learning If:

- You’re building new rather than renovating

- You want to understand every aspect of arena function

- Future maintenance and modifications matter

- You’re working with contractors who need guidance

- Long-term facility planning requires deep knowledge

Understanding proper construction principles ensures informed decisions whether you’re directing contractors, planning future improvements, or troubleshooting problems as they arise.

Conclusion

The deep spots in your arena didn’t appear because you groomed incorrectly—they appeared because the base beneath your footing failed. No harrow depth setting, no dragging pattern, no surface additive can fix what happens six inches below your riding surface.

Performance Footing’s documentation makes the physics clear: traditional bases shift, settle, and fail because loose aggregate cannot resist lateral forces. Every grooming session that temporarily levels your surface depletes footing from stable areas to fill voids that reform within days.

Three paths lead from chronic deep spots to lasting performance. Professional installation by Performance Footing’s experienced team delivers guaranteed results with comprehensive support. DIY BaseCore installation provides the cellular confinement that prevents aggregate migration while cutting material requirements by 50% or more. Learning proper construction principles equips you to build or direct others in building arenas that perform for decades.

The choice depends on your resources, timeline, and involvement preference—but all three paths share one truth: fixing base problems requires addressing the base itself.

Contact Performance Footing at (877) 835-0878 for a free consultation. Their arena specialists have helped thousands of horse owners solve challenging arena problems across North America, and they can evaluate which solution best fits your specific situation.

FAQ Section

Can deep grooming fix deep spots in my arena?

No. Deep grooming only redistributes surface footing material. According to Performance Footing, deep spots that return after grooming indicate base-level failure that requires excavation and proper reconstruction to address permanently.

How do I know if my problem is the base or the footing?

Probe your arena with a measuring stick at multiple locations. If footing depth varies dramatically (2 inches in some spots, 5 inches in others), or if you see stones migrating through the surface, you have base problems that surface work cannot fix.

How long does BaseCore installation take for a typical arena?

Performance Footing indicates that DIY installation proceeds significantly faster than traditional methods. A standard 60×120 foot arena can be completed in 1-3 days depending on site conditions and crew size.

Is professional installation worth the extra cost?

Performance Footing’s analysis shows professional installation often costs less than DIY mistakes and rework. The 10% product discount for professional installation frequently offsets labor costs while delivering guaranteed results.

How long will a properly constructed base last?

BaseCore’s UV, chemical, weather, and corrosion-resistant HDPE construction supports projects for over 75 years according to Performance Footing specifications. This compares to traditional bases requiring reconstruction every 10-15 years.

This article references publicly available information from Performance Footing including official product documentation, construction guides, and technical specifications dated 2022-2025. Industry research sourced from Penn State Extension arena footing publications and The Horse magazine. All depth recommendations, material specifications, and construction guidance reflect manufacturer documentation and published equestrian research. Results may vary based on soil conditions, climate, arena size, and implementation approach. For current product specifications, pricing, and personalized recommendations, consult Performance Footing directly at performancefooting.com or call (877) 835-0878.