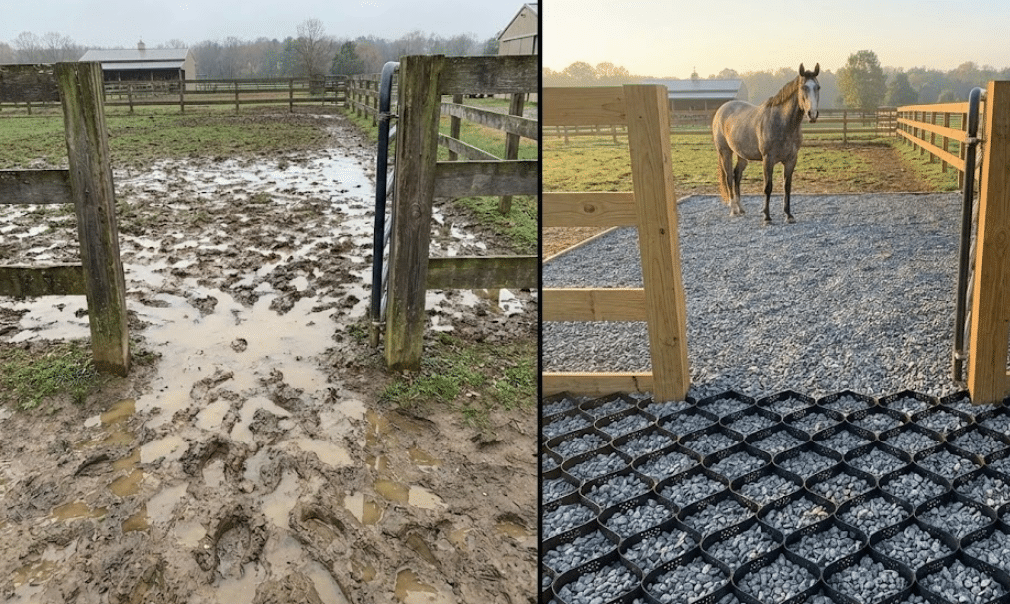

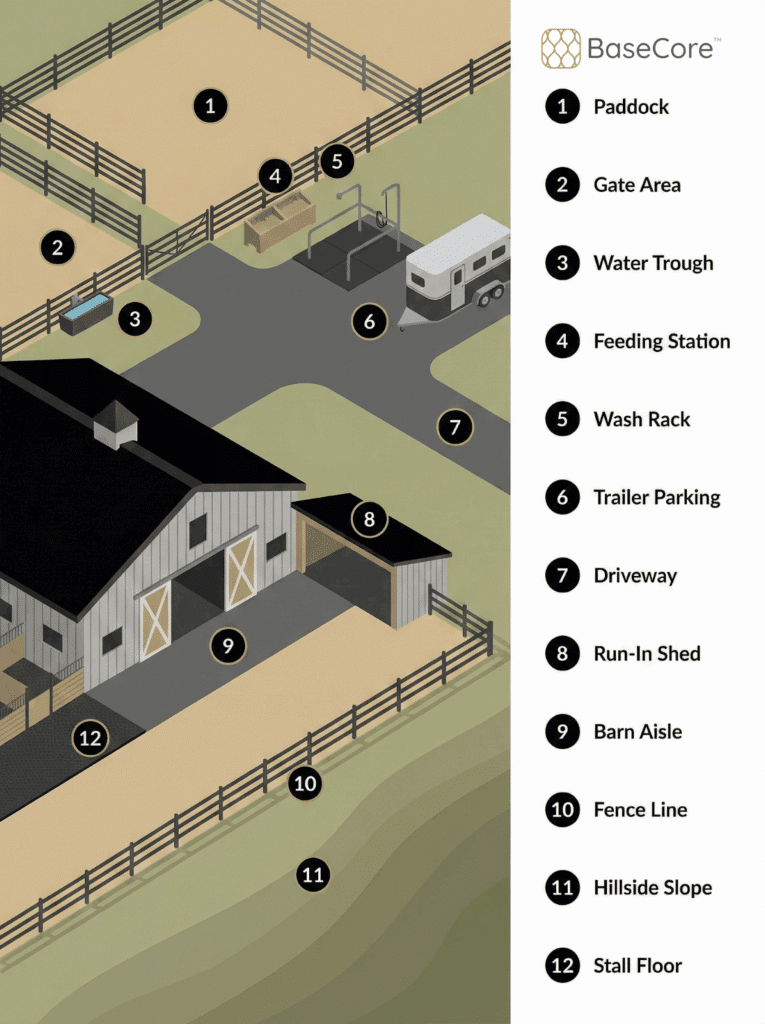

The morning feed routine should be simple—walk to the barn, distribute hay, check water. Instead, many facility owners navigate muddy obstacle courses from gate to feed room, boots getting sucked into muck with every step. According to Performance Footing’s documentation on high-traffic barn areas, the wash rack becomes a swamp, trailer parking looks like a demolition derby track, and the disaster zone around water troughs never improves. While arena footing gets most of the attention, these everyday barn areas create the most frustration and ongoing expense. This guide examines 12 specific applications where BaseCore geocell technology delivers measurable returns across your entire facility.

Understanding BaseCore Technology for Barn Applications

Before examining specific applications, understanding BaseCore’s fundamental mechanism explains why it works across such diverse uses. According to Performance Footing’s product documentation, BaseCore is a durable ground stabilization grid made from high-density polyethylene (HDPE) plastic that distributes weight, locks in fill materials, and prevents ruts, mud, and erosion.

The technology originated with the U.S. Army Corps of Engineers in the 1970s for building roads over soft ground. Performance Footing adapted this military-grade engineering specifically for equestrian and agricultural applications. The honeycomb structure creates what engineers call “apparent cohesion”—turning loose aggregate into a unified, stable surface.

Performance Footing’s specifications indicate that using just 3 inches of BaseCore provides the same strength as 12 inches of gravel alone. This efficiency creates the ROI foundation for every application that follows.

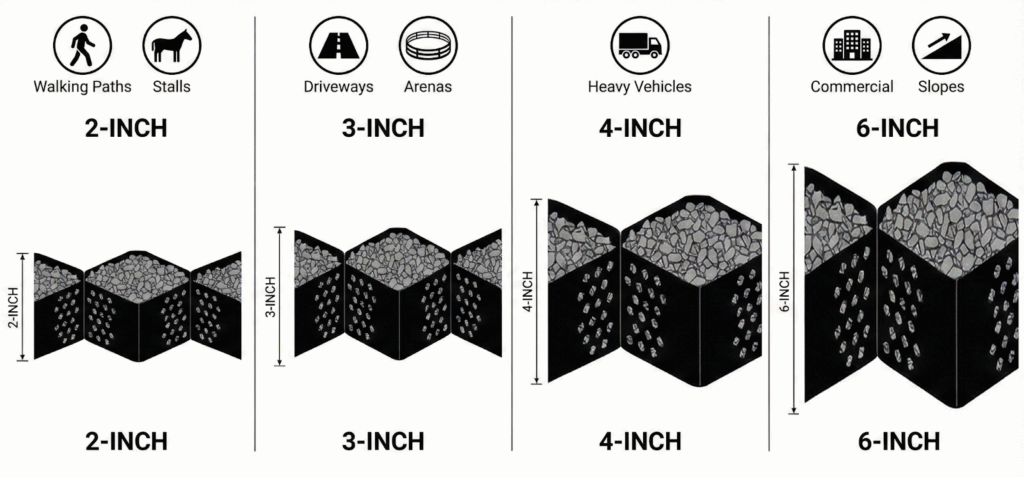

Selecting the Right Panel Depth

Performance Footing recommends specific panel depths for different equestrian uses:

2-inch panels: Ideal for grooming paths, stall floors, and wheelbarrow access in light-duty, pedestrian applications.

3-inch panels: Great for arenas, runs, parking areas, and private driveways supporting light vehicles and trailers.

4-6+ inch panels: Best for slow-draining areas, muddy paddocks, erosion control, slope retention, and heavy-duty reinforced applications.

The BaseCore HD variant features cell sizes almost 50% smaller than standard geocell products and 35% smaller than standard BaseCore, making it the choice for demanding equestrian needs around horses and livestock, steeper grades, and high-stress zones.

The 12 High-ROI Applications

1. Paddock and Turnout Stabilization

Paddocks represent the most common mud management challenge on equestrian properties. Horses congregate, pace fence lines, and create high-traffic patterns that destroy traditional surfaces within weeks of wet weather.

According to Performance Footing’s paddock stabilization guide, geocell technology offers a transformative solution for these environments. The three-dimensional honeycomb structure confines and stabilizes aggregate within individual cells, preventing the lateral movement that creates ruts and mud pits.

Implementation specifications:

- Recommended depth: 3-4 inch BaseCore HD for areas with horse traffic

- Fill material: 5/8-inch minus crushed stone with angular edges for optimal compaction

- Coverage: Fill cells completely plus an additional 2-inch layer on top for horse comfort

The geocell structure promotes excellent drainage while preventing soil from rising up through the aggregate—a common failure mode in traditional gravel-only approaches. This leads to decreased hoof-related issues and cleaner, more manageable paddock environments.

2. Gate Areas and High-Traffic Zones

Gateway areas typically show the first signs of mud problems, according to Performance Footing’s documentation. Horses naturally congregate near entrances and exits, creating concentrated pressure that destroys ground surfaces faster than any other location.

Performance Footing’s high-traffic barn area guide notes that BaseCore’s honeycomb structure turns loose materials into solid, stable surfaces by acting like miniature retaining walls. Each cell prevents the lateral movement that creates ruts and mud, while the distributed weight eliminates point loading that causes traditional surfaces to fail.

Implementation specifications:

- Recommended depth: 3-inch BaseCore HD minimum

- Extend coverage at least 10 feet in each direction from gates

- Use angular aggregate for maximum interlock within cells

3. Water Trough Surroundings

Areas around water troughs face unique challenges from constant moisture combined with concentrated traffic. Horses pawing at water create mud volcanoes, while competition at troughs turns surrounding ground into persistent problem zones.

Performance Footing’s implementation guidance recommends extending BaseCore at least 8 feet from the trough in all directions to accommodate splashing and overflow. Creating a slight slope away from the trough prevents water accumulation, while the perforated cell walls allow drainage while maintaining surface stability.

Implementation specifications:

- Recommended depth: 3-inch BaseCore HD

- Extend 8+ feet from trough perimeter

- Create 1-2% slope away from trough

- Consider French drain beneath BaseCore for areas with automatic waterers

4. Feeding Stations

Feeding stations experience heavy traffic combined with organic waste that accelerates surface degradation. Horses competing for food create tremendous ground pressure and lateral movement that destroys traditional surfaces.

BaseCore contains the aggregate, preventing creation of holes and high spots that cause horses to stumble or compete more aggressively, according to Performance Footing’s documentation. The stable surface also reduces feed waste from hay falling into mud and becoming inedible.

Implementation specifications:

- Recommended depth: 3-inch BaseCore HD

- Extend coverage 6-8 feet beyond feeder footprint

- Fill with well-draining aggregate

- Consider rubber mulch top layer for extended standing comfort

5. Wash Rack Areas

Wash racks experience constant water exposure combined with horse traffic—a combination that destroys traditional surfaces rapidly. The cellular structure of BaseCore allows water to drain vertically through the aggregate while maintaining surface stability.

According to Performance Footing’s documentation, areas that once became impassable after use remain firm and usable immediately. The perforated cell walls create natural drainage channels while the honeycomb structure prevents aggregate migration.

Implementation specifications:

- Recommended depth: 3-4 inch BaseCore HD

- Use well-draining aggregate (clean gravel works well in wash areas)

- Install geotextile fabric beneath BaseCore to prevent soil mixing

- Size area to accommodate full wash process including drying

6. Trailer Parking Areas

Trailer parking areas support some of the heaviest loads on any equestrian property. Loaded horse trailers create point loading that destroys loose gravel surfaces, creating ruts that worsen with each use.

Performance Footing’s farm applications guide states that BaseCore provides strength for driveways and parking spots that withstands tractors, trucks, and trailers. The cellular confinement distributes loads across greater surface area, eliminating the rutting that plagues traditional gravel lots.

Implementation specifications:

- Recommended depth: 3-inch BaseCore HD for standard trailers; 4-inch for commercial operations

- Size for complete turning radius plus parking

- Use angular crushed stone for maximum load distribution

- BaseCore HD double-weld seams provide tensile strength over 2,000 lbs per square foot

7. Driveways and Access Roads

Farm driveways suffer from tire spin, heavy vehicles, and erosion that requires constant gravel replacement. According to Backyard Bases documentation, gravel driveways often suffer from ruts, potholes, and washouts due to traffic and weather.

BaseCore holds aggregate material in cells that keep it from being pushed down into the sub-base, which creates the uneven surfaces that characterize failing driveways. The perforated panels allow water to pass through without washing out material.

Implementation specifications:

- Recommended depth: 3-inch for residential driveways; 4-inch for heavy equipment access

- Width: Plan for occasional two-vehicle passage

- Use 3/4-inch minus angular aggregate

- Excavation depth using geocells is 1/3 of what gravel-only methods require

8. Run-In Shed and Loafing Shed Foundations

Building foundations on equestrian properties face unique challenges from both load requirements and drainage needs. Traditional concrete creates runoff problems while gravel alone settles unevenly.

According to Backyard Bases farm documentation, BaseCore provides strength to any building on your farm, including barns, greenhouses, and loafing sheds, using the same geocell foundation civil engineers rely on for highways and airstrips.

Implementation specifications:

- Recommended depth: 4-inch BaseCore HD for permanent structures

- Extend beyond building footprint to manage roof runoff

- Combine with geotextile fabric for maximum stability

- Create slight grade away from structure for drainage

9. Barn Aisle Stabilization

Barn aisles experience constant traffic from horses, people, and equipment. The combination of traffic patterns and potential moisture from wash stalls, grooming, and weather creates ongoing maintenance challenges.

Performance Footing’s product specifications indicate that 2-inch BaseCore panels are ideal for grooming paths, stall floors, and wheelbarrow access in light-duty applications. This lighter profile maintains stability while minimizing material costs.

Implementation specifications:

- Recommended depth: 2-inch BaseCore HD for pedestrian and horse traffic

- Fill with appropriate aggregate or rubber mulch for cushioning

- Install geotextile fabric beneath to prevent soil migration

- Works in both covered and open aisle configurations

10. Fence Line Maintenance Paths

Fence lines become muddy maintenance nightmares from horses pacing and congregating. According to Backyard Bases documentation, paddocks and fence lines are notorious for mud problems that are difficult to manage.

BaseCore panels lock ground between honeycomb structures, stopping mud pits before they start and protecting land from heavy storms and erosion. The flexible panels conform to natural terrain variations common along fence lines.

Implementation specifications:

- Recommended depth: 2-3 inch BaseCore depending on traffic intensity

- Width: 4-6 feet along high-traffic fence sections

- Focus on corners and gate approaches where horses congregate

- Flexible panels accommodate natural ground contours

11. Hillside and Slope Stabilization

Sloped areas around barns create erosion challenges that worsen each season. Runoff carries away topsoil, creates gullies, and undermines structures.

According to BaseCore’s slope protection documentation, geocell panels lay directly on grades and protect hillsides with honeycomb structure. The slope’s bearing capacity increases as the base withstands years of hydraulic and mechanical stresses.

Performance Footing notes that BaseCore conforms to the natural shape of your land, making it ideal for sloped turnouts, hillside trails, uneven barn entrances, and other non-flat areas.

Implementation specifications:

- Recommended depth: 4-6 inch BaseCore HD for significant slopes

- Can be vegetated with grass growing through cells

- Eliminates expensive gabion stones, rip rap, and concrete

- Allows use of on-site soil as infill to reduce material costs

12. Stall Floor Drainage Layer

Stall floors require stable, well-draining bases that maintain integrity under constant use. Traditional approaches often fail at the drainage layer, creating moisture problems that affect horse health.

Performance Footing’s stall drainage guide explains that BaseCore serves as an ideal foundation for stalls and runs. The design ensures even distribution of weight, reducing ground rutting and compaction—two factors that contribute to poor drainage.

Implementation specifications:

- Recommended depth: 2-inch BaseCore HD for stall applications

- Combine with geotextile fabric for maximum effectiveness

- Top with appropriate stall bedding

- Allows moisture to channel away effectively, preventing pooling

Universal ROI Factors Across All Applications

Material Savings

Performance Footing documentation indicates that BaseCore reduces aggregate, soil, and concrete infill by up to 50% for load support applications. The excavation depth using geocells is 1/3 of what gravel-only methods require, reducing both material and labor costs.

Longevity

With UV, chemical, weather, and corrosion-resistant construction, BaseCore supports projects for over 75 years according to Performance Footing specifications. Unlike concrete, the panels won’t crack under extreme temperatures, and they’re even reusable for new projects if needs change.

Installation Simplicity

Performance Footing states that you don’t need formal training to install BaseCore. Two or more people with simple tools and equipment can build reliable bases without hiring specialists. The company provides installation guides covering their straightforward 6-step process.

Adaptability

Unlike concrete and steel, BaseCore panels can be cut to fit around drainage pipes, trees, and other obstacles. The geocell foundation grids accommodate any length and width, with custom sizing available for non-standard projects.

Implementation Guide: Universal Steps for Any Application

Step 1: Site Assessment

Evaluate existing conditions including soil type, drainage patterns, traffic intensity, and slope. Clay-heavy soils benefit from additional drainage considerations. Note any existing problem areas and water flow patterns.

Step 2: Excavation and Preparation

Remove topsoil and vegetation to expose subgrade. Performance Footing notes that excavation depth is approximately 1/3 of what traditional gravel installations require. Compact native soil and establish proper grade with 1-2% slope toward drainage areas.

Step 3: Geotextile Installation

Lay commercial-grade 6oz non-woven geotextile fabric across the prepared area. Performance Footing offers 12.5×360 feet rolls that provide excellent coverage. Overlap seams by 8-12 inches to prevent soil migration.

Step 4: Panel Deployment

Expand BaseCore panels accordion-style to full dimensions. Position on geotextile and secure adjacent panels using BaseClips connection system. Anchor to subgrade using BaseCaps, which sit flush and remain safe for traffic.

Step 5: Aggregate Fill

Fill expanded cells with appropriate aggregate—typically 3/8-inch to 3/4-inch minus crushed stone depending on application. Extend fill approximately 2 inches above cell walls. Compact using vibrating plate compactor.

Step 6: Final Grading

Grade surface to ensure proper drainage and uniform coverage. Check that all cells are completely filled and compacted. For areas where horses will stand, ensure adequate depth above cells for comfort.

Selecting the Right Product for Each Application

BaseCore Standard

Performance Footing describes standard BaseCore as great for slopes, under turf, and light-duty jobs. Cell dimensions are larger, making it economical for applications without heavy traffic or loads.

Best for: Fence line paths, light pedestrian areas, vegetation stabilization, turf reinforcement

BaseCore HD

BaseCore HD is engineered for heavier traffic, animals, and steeper slopes according to Performance Footing. The smaller cell size—almost 50% smaller than standard geocell products—provides superior strength with less fill material.

Best for: Paddocks, gate areas, driveways, trailer parking, any area with horse or vehicle traffic

Depth Selection Summary

| Application | Recommended Depth | Product |

| Grooming paths, stall floors | 2″ | BaseCore HD |

| Barn aisles, walkways | 2″ | BaseCore HD |

| Arenas, runs, light driveways | 3″ | BaseCore or HD |

| Paddocks, trailer parking | 3-4″ | BaseCore HD |

| Heavy vehicle access, slopes | 4-6″ | BaseCore HD |

Common Mistakes to Avoid

Insufficient Coverage Area

Gateway areas and water trough surroundings need larger treatment zones than the immediate problem area. Performance Footing recommends extending coverage 8-10 feet beyond visible problem zones to prevent edge deterioration.

Skipping Geotextile Fabric

The geotextile layer prevents soil migration into aggregate and maintains long-term drainage efficiency. Performance Footing emphasizes using this fabric beneath BaseCore geocells to prevent the foundation from sinking into the subgrade.

Inadequate Compaction

Proper compaction of both subgrade and aggregate fill determines long-term performance. Use vibrating plate compactor, not just vehicle traffic, to achieve complete settlement within cells.

Wrong Aggregate Type

Round gravel shifts within cells. Performance Footing recommends angular crushed stone for maximum interlock and stability. The “minus” designation (3/8″ minus, 3/4″ minus) indicates presence of fines that improve compaction.

Conclusion

The muddy paddock entrance, the rutted driveway, the swampy wash rack—these aren’t inevitable features of equestrian facility ownership. BaseCore geocell technology, originally developed by the U.S. Army Corps of Engineers and adapted by Performance Footing for equestrian applications, provides 75+ year solutions for every problem area around your barn.

The consistent principle across all 12 applications is cellular confinement: turning loose aggregate into stable, unified surfaces that drain freely while supporting horses, vehicles, and equipment. With material savings of up to 50% compared to traditional methods and DIY installation requiring no specialists, the ROI calculation favors action over continued mud management.

Contact Performance Footing at (877) 835-0878 for a free consultation on which applications would deliver the greatest return for your specific facility. Their engineering team provides product specifications, testing data, and professional guidance for projects of any scale.

FAQ Section

How many BaseCore panels do I need for a typical paddock gate area?

A standard gate area treatment covering 10×10 feet requires approximately one 3-inch BaseCore HD panel (10×12 feet). Performance Footing offers free project evaluation to calculate precise requirements for any application size.

Can BaseCore be installed over existing mud?

No. Performance Footing’s installation guide requires removing topsoil and vegetation to expose stable subgrade before installing geotextile and BaseCore layers. Installing over mud compromises long-term stability.

What maintenance does BaseCore require after installation?

According to Performance Footing specifications, properly installed BaseCore requires virtually no ongoing maintenance for its 75+ year lifespan. Periodic inspection and minor aggregate replenishment in high-wear areas may be needed.

Is BaseCore safe for horses to stand on?

Yes. Performance Footing states that once installed and filled, BaseCore creates a safe, slip-resistant surface that prevents hoof damage, joint strain, and leg injuries while eliminating deep mud and rutting hazards.

Can I install BaseCore myself?

Yes. Performance Footing indicates that two or more people with simple tools can install BaseCore without formal training. The company provides installation guides and video tutorials covering the straightforward 6-step process.

This article references publicly available information from Performance Footing and Backyard Bases including official product documentation and technical specifications dated 2022-2025. All depth recommendations, material specifications, and application guidance are from manufacturer documentation. Results may vary based on soil conditions, climate, traffic intensity, and implementation approach. For current product specifications, pricing, and personalized recommendations, consult Performance Footing directly at performancefooting.com or call (877) 835-0878.