When looking for ground reinforcement, consumers are often stuck comparing several similar (but fundamentally different) materials. For reinforcing roads, slopes, and embankments, the choice usually comes down between two main support materials: Geocells and Geogrids.

Both materials are part of the geotechnology category– sturdy materials developed to be placed over a subgrade and used to prevent excess soil erosion and structural weakness. While either solution can be used, depending on the project you are completing, one material may have marked advantages over the other.

In this article we will go through a side-by-side comparison of Geocell vs Geogrid, covering some of the main areas that will help you decide on which material is right for you.

Physical Structure and Support

The physical structure of your geotech material will largely affect the way it provides ground support and how much support it can realistically provide.

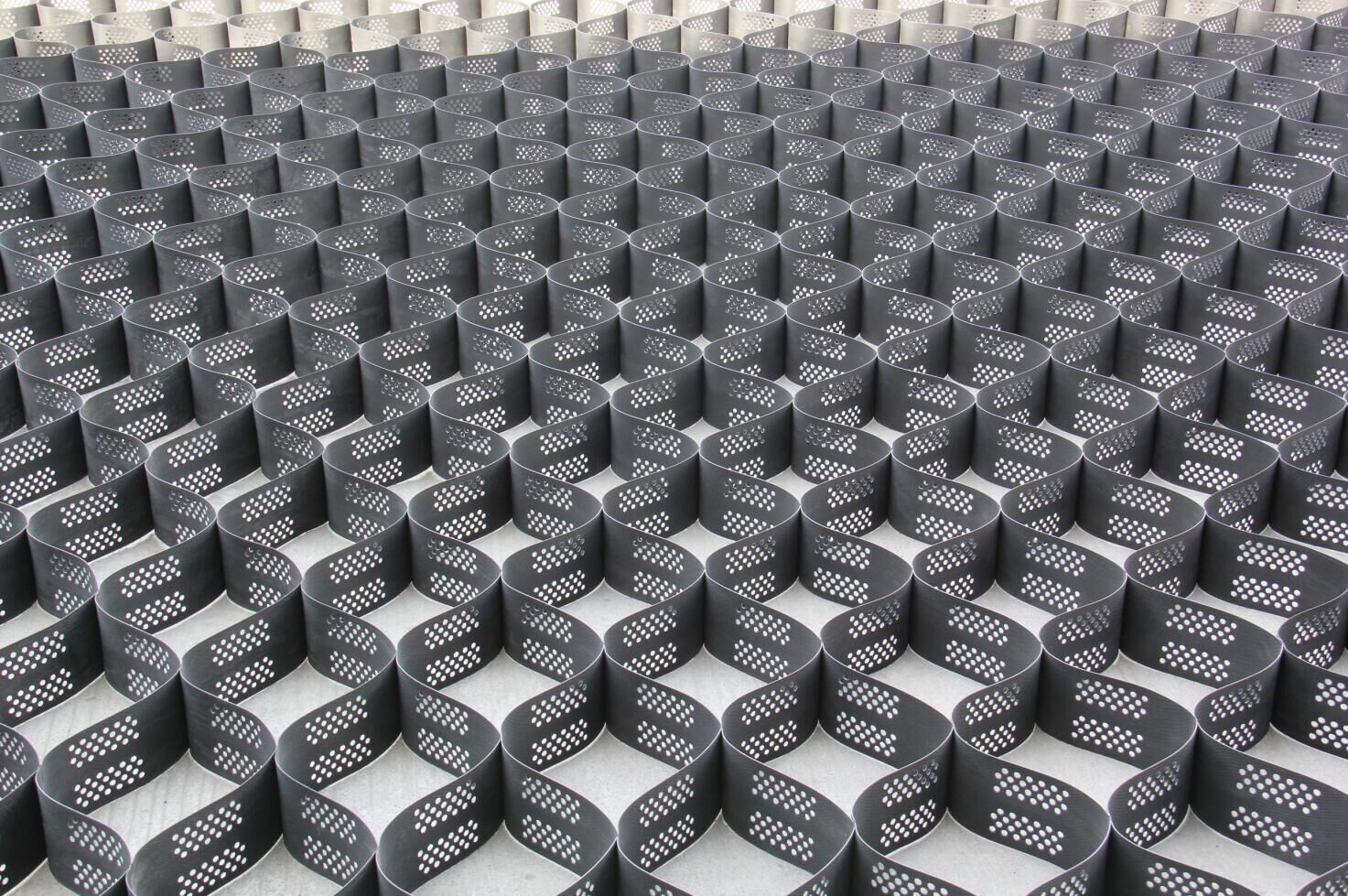

Geocells are deep, three-dimensional structures. They interlock in a pattern that much resembles an unfoldable honeycomb, providing sheets of pocket-like cells designed to contain whatever infill you choose.

This structure provides a few marked benefits. For one, the pocket-like nature of geocells supports the infill of your choice from all angles. Over time, this results in far less weather erosion, compacting, or shifting of the material. As such, geocells also provide superior drainage by allowing the natural flow of water around your infill, unencumbered by the restrictions brought on by compacted materials.

Geogrids, on the other hand, are two-dimensional. This means they have increased flexibility but greatly reduced support. The remedy to this problem is not ideal as it requires layering sever geogrids on top of one another. Even when upwards of 3 layers are used, it still does not fully resolve the support issues, leaving you susceptible to weather erosion, compacting, and poor drainage.

As such, geogrids are commonly used where thin separation or flexible top support is needed. For instance, securing the top, external layer of a slope of embankment.

Infill Material Restrictions

Once again, the 2D vs. 3D structure of geogrids and geocells has the largest impact on which infill materials you can reasonably expect to use. Of the two materials, geocells offer the ability to support a larger variety of infill materials.

Due to their unparalleled support, geocells can support and make use of a wide variety of infill materials. In fact, you can use whatever is on hand and native to the area you are working in– even sand. So long as the material can be disbursed into each pocket, the material can be used as infill and still be adequately supported. When trying to keep project costs down, this allows for the use of less-than-ideal infill materials with little sacrifice to the end result.

Geogrids are far more finicky. Their lower level of initial support reduces the number and effectiveness of various infills and thus requires the use of well-graded, high quality aggregate. Depending on your location size and pre-existing soil conditions, the cost of this kind of infill can add up quickly– depleting any savings provided by the reduced cost of the geogrids themselves.

Performance Over Soft Subgrades

Depending on your location, you may be dealing with the struggle of building over a soft subgrade. Even with proper preparation, this particular issue cannot always be entirely resolved, making geocells the safer and more economical choice to continue construction.

Because of the strong vertical support of each cell, geocells are less prone to bending and sinking into the subgrade over time. This rigidity also makes them easier to install– simply unfurl in position and fill with substrate.

For roads or other load-bearing surfaces, this saves time and money in the long run by giving the underside of the road unparalleled support. The less this support shifts, the less road damage will occur.

Geogrids do not perform well on soft subgrades because the thin flexible material is difficult to properly install. In order to provide support, geogrids need to be laid flat and pulled taut– something very difficult to accomplish on less than ideal subgrades. Furthermore, in order to bear heavy loads such as vehicle traffic, sometimes 2 or 3 layers of geogrids will need to be placed and filled on top of one another to have the desired effect. As such, the cost of your project will increase with each needed layer.

In addition to leaving the road poorly supported, improper installation and natural vertical flexibility could result in sagging– eventually causing cracks and major structural damage to the surface above. Over time, the result will be a road that needs regular and costly maintenance that could have otherwise been avoided.

Overall Cost

Geocells typically outperform geogrids in both the short and long-term– cost is no exception.

While geocells may be slightly less cost effective to purchase initially, they require less maintenance and material refills over time. The greatly reduced material and maintenance costs of geocell-supported areas ends up paying for the initial cost of the cells in the long run.

Furthermore, when dealing with grounds that are less than ideal, the self-supporting nature of geocells will require less material while offering more support. Unlike geogrids, Geocells will rarely need more than one layer to support a roadway and, if building an embankment or other similar structure, can be easily stacked for fast building vertical support.

Sourcing Your Materials

If you have determined that geocells are the right material for your next project, Performance Footing has you covered. As a family-owned, Arizona-based vendor of geocell technologies, we are proud to offer unparalleled service and pricing for your project needs. Either purchase directly from the box below or give us a call with any question you might have at (877) 835-0878.